Umatshini wokushicilela ngokuzenzekelayo ye-hymaulic

Izinto zomatshini: Cinezela (kubandakanya iphakheji ye-backnetity), isikhululo solawulo lombane, IKhabhinethi yoMbane, inaliti kunye nenkqubo yokudibanisa, itanki le-vacuum; Isakhelo sobulqwa, esizenzekelayo esingenanto yokuthatha umatshini.

Whatsapp: +86 176 0282 8986

Inkcazo yesiseko sobugcisa

I-1) I-gear ye-pump ye-pump senraulic inkqubo isetyenziselwa ukupholisa ioyile yoxinzelelo ukuqinisekisa uxinzelelo, uzinzo kunye nokuthembeka xa umshicileli usetyenziswa ixesha elide;

2) Ukusetyenziswa kwamandla aphantsi kunye nokugcinwa kwamandla. Ukuselwa kwamandla kuMatshini uphela kuyafana ne-150-ton-ton, kwaye ukukhutshwa kotshintsho ngama-53% ngaphezulu kwe-150% yoovimba;

3) Isiseko sombuso esiqhelekileyo simiselwe kumgcini, kwaye amalungu abunjiweyo anokubuswa ngokukhawuleza kwaye atshintshwe xa isisu sithathelwe indawo, kwaye isiseko sokubumba sizimele sizimele;

4) Owona mzimba uphambili yintsimbi epheleleyo yentsimbi (okanye i-Iron okanye i-iron yentsimbi), kunye neendawo ezingaphantsi nezisezantsi zomsebenzi, iziseko zobumba, i-wire ye-wire eboshwe yintsimbi. Ukomelela kwamanyathelo aphezulu, isakhiwo secandelo, indawo encinci yokufaka, efanelekileyo yokufaka incwadana yemigaqo okanye ezenzekelayo.

I-5) Iyunithi ephambili kulwakhiwo lwekholam ezine, elinika indawo ephezulu ye-Wire ePhezulu.

6) Iscreen sekrelekrele kunye ne-Ensor yokufumana i-intanethi-yoomatshini, ukulungisa ingxaki kuyinto efanelekileyo kwaye ngokukhawuleza;

I-7) Izinto ze-hydraulic zesikhululo soxinzelelo oluphezulu sisebenzisa i-valves yobugcisa yase-Italiya,

8) Yanelisa imixholo yamanzi asezantsi (34% yomxholo wamanzi) Inaliti esenzekelayo, eqinile kwaye ethembekileyo

Imeko yenkampani

Iiparamitha zomatshini

| Igama | Iyunithi | Ixabiso | |

| Imodeli | / | Yf-230t | |

| I-cylinder ephezulu | KN | 2300 | |

| Ububanzi be-cylinder ephezulu | mm | I-360 | |

| I-sylinder ephezulu | mm | I-495 | |

| I-cylinder esezantsi | KN | I-1000 | |

| I-cylinder esezantsi | mm | I-250 | |

| I-cylinder esezantsi | mm | I-145 | |

| Isantya se-RAM | Ukuvala | mm / s | >I-180 |

| Indlela yokuhamba kancinci | mm / s | 2-10 | |

| Ukucofa kancinci | mm / s | I-0.02-1.5 (ihlengahlengiswa) | |

| Ukucinezela ngokukhawuleza | mm / s | I-0.1-2.5 (iguqukile) | |

| Buyela | mm / s | >90 | |

| Isantya sethu | Khupha | mm / s | 20 |

| Buyela | mm / s | 35 | |

| UMax. indawo yasimahla ye-ephezulu kwaye iphantsi | mm | I-1080 | |

| Ubungakanani obusebenzayo (ubude be-x ububanzi) | mm | I-1460 × 860 | |

| Iphakheji ye-Wire ePhezulu yoMoya | / | I-Coitneting epholileyo ye-Airnetice Coil 100000AMpere-jika | |

| UMax. ivolumu yenja yejeyi | L | 4.1 | |

| UMax. Ukulayisha umxube | L | I-180 | |

| Amandla onke aMatshini wonke | KW | 65 | |

| Isiseko sokungena | / | I-550mm Gap phakathi kweZiseko zoMnyama, ubude bama-300mm | |

| Ixesha lomjikelo | S | <60 | |

Intsika

Iikholamu zesikhokelo (iintsika) ziya kwenziwaI-C45 ishushu intsimbi yentsimbikwaye ube ne-chrome enzima ye-chrome i-0.08mm. Kwaye wenze lukhuni kwaye unyango.

Umzimba ophambili

Uyilo lwalo matshini uphela uyayime i-Computer Applisotion yoyilo kunye nohlalutyo ngenqaku eligqibeleleyo. Amandla kunye nobungqola bezixhobo zilungile, kwaye imbonakalo intle. Zonke iindawo zedilda ze-Welding zidlwengulwe yi-Wieel Mill Mill Q345B Playiti, eDelid ngekhabhoni ye-Carbon ukuqinisekisa umgangatho we-welding.

Isilinda

| Amalungu | Fukutya |

| I-cylinder barrel |

|

| Piston rod |

|

| Amatywina | Ukwamkela uMgangatho weNqaku loMgangatho wokutywina |

| Piston | Ukukhokelwa ngubhedu ngobhedu, ukunyangwa okuhle, qinisekisa ukusebenza ixesha elide ngesilinda |

Inkqubo ye-servo

I-1.Nerservo yenkqubo

Umgaqo wokulawulwa kwe-servo

I-cylinder ephambili yegumbi eliphezulu elixhotyiswe ngenzwa yoxinzelelo, isilayidi esineqhinga eline-Sensor Sensor. Ngokutsho koxinzelelo lwengxelo, isibonakaliso sengxelo, isikhundla esinikiweyo, isikhundla esinikiweyo kunye nesantya esinikiweyo ukubala isantya esijikelezileyo se-serno, isantya sokukhuphela itrayi, isantya kunye nolawulo lwempompo.

Umatshini wokushicilela amkele i-PID ukuze atshintshe uxinzelelo kunye nesikhundla, ngesantya se-serso motor motoll wandulela uLawulo lweLoop oluvaliweyo. Ngokuhlengahlengisa isantya se-serso motor, inokulawula uxinzelelo, isantya, isikhundla kunye nezinye iiparamitha ze-hydraulic, ngokuphelisa i-valve yokulawula uxinzelelo isekethe yesiphaluka ukuba senze lula isekethe.

3.AMjelo wenkqubo ye-servo

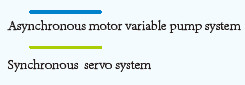

Ukugcina amandla

Xa kuthelekiswa nenkqubo yempompo eyahlukileyo, inkqubo ye-Insevo ye-oyile idibanisa imizobo yesantya ekhawulezileyo ye-serno kunye nokulawula amandla e-oyile ye-hydraulic, kunye namandlaIxabiso logcino linokufikelela kwi-30% -80%.

Ngokufanelekileyo

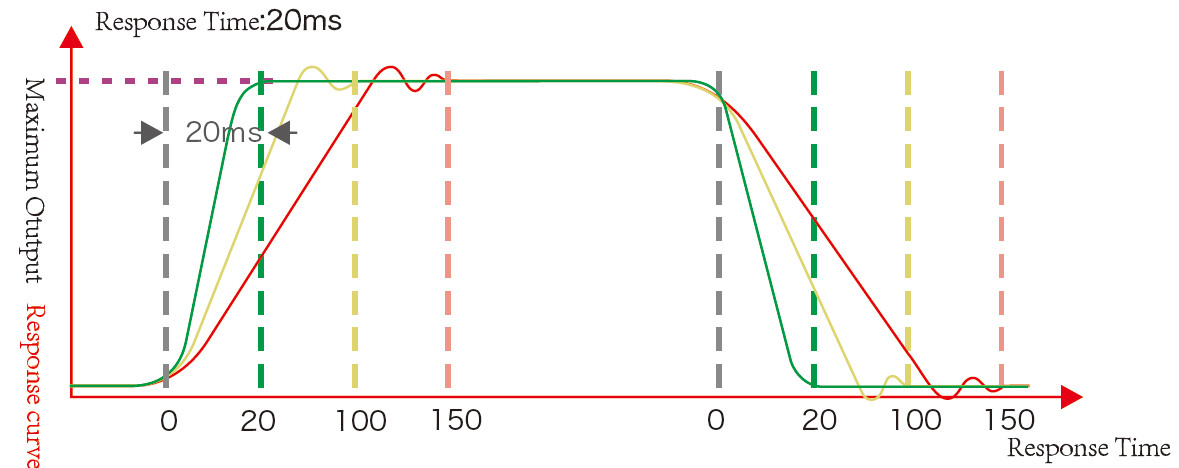

Isantya sokuphendula sikhawuleza kwaye ixesha lokuphendula lifutshane njenge-20ms, eliphucula isantya sempendulo senkqubo ye-hydraulic.

Ukuchaneka

Isantya sempendulo ekhawulezileyo siqinisekisa ukuchaneka nokuvalwa kokuvula, imeko yokuchaneka inokuthi ifikelele kwi-0.1MM, kunye nendawo ekhethekileyo yokusebenza kokubekwa kwindawo ye-0.01mm.

Imodyuli ephezulu ye-algorithm iqinisekisa uxinzelelo lwenkqubo oluzinzileyo kunye noxinzelelo lwezinto ezingaphantsi kwe- ± 0.5 ze-0.5 bar, ukuphucula umgangatho wemveliso.

UKUKHUSELEKELA KWESICELO

Ingxolo: Ingxolo yengxolo ye-hydraulic senso yenkqubo ye-15-20 DB iphantsi kunelo mpompo yokutshintsha.

Iqondo lokushisa: Emva kwenkqubo ye-servo isetyenziswa, iqondo lobushushu le-hydraulic lincitshisiwe lilonke, ephucula ubomi betywina le-hydraulic okanye inciphise amandla okupholisa.

Inkqubo

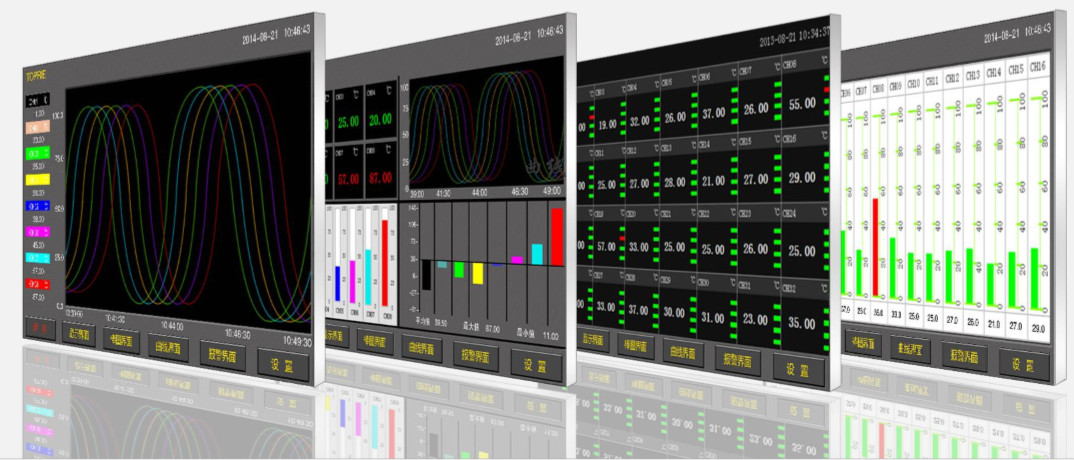

Ikhompyutha ye-Multi-Screen mzi mveliso inolwazi lweeparamitha eziphambili kunye neempazamo zomatshini wokushicilela, ubukhulu becala zibandakanya le ngcaciso ilandelayo:

● Ijika(Mpa, ℃) ● I-password ikhuselwe nge-password ● Umboniso wedijithali ● Ukulandelwa kwedatha

| Isikhundla se-0 Ukuphelisa umoya | Umjikelo wonyango, inqanaba kwiNkqubo.clamp yoxinzelelo Isantya

|

Isixhobo sokhuseleko

I-Photo-Short-Umbane woMbane

Ukutshixwa kwesilayidi kwi-TDC

Umsebenzi ombini wezandla

Isekethe ye-Inshurensi ye-Hydraulic

Ukukhuselwa okungaphezulu: I-Valve Erveve

I-Alarm yenqanaba le-wolity: inqanaba leoyile

Isilumkiso seqondo lobushushu leoyile

Inxalenye nganye yombane ilayisha ngaphezulu

Iibhloko zokhuseleko

Izitshixo zinikezelwa kwinxalenye eshukumayo

Lonke inyathelo lokushicilela lunemisebenzi yophuhliso lokhuseleko, umz. Ukususwa kwemali akuyi kusebenza ngaphandle kokuba i-caushion ibuyela kwisikhundla sokuqala. Isilayidi asinakucinezela xa kunyanzelekile ukuba inyanzeliswe. Xa umsebenzi wengxabano yenzeka, i-alamu ibonisa kwiscreen sodidi kwaye ibonise ukuba yintoni impikiswano.

Inkqubo ye-hydraulic

Inqaku

I-1.oil Tok icwangcisiwe inkqubo yokuphola i-Filthalling (ukupholisa nge-oyile chiller, iqondo lobushushu le-oyile

Inkqubo ye-Hydraulic yamkela inkqubo yokulawula i-velidge ye-velidge yesantya sokuphendula ngokukhawuleza kunye nokusebenza okuphezulu.

3.Itanki yeoyile ixhotywe ngentloko yomoya ukunxibelelana ngaphandle ukuqinisekisa ukuba ioyile ye-hydraulic ayingcolwanga.

4.Unxibelelwano phakathi kwevalve yokuzalisa kunye netanki yamafutha isebenzisa i-cuntry edibeneyo ukuthintela ukuntywila kwitanki yamafutha kwaye isombulule ngokupheleleyo ingxaki yokuvuza ioyile.

5.Umbhobho weoyile ye-hydraulic wenza ikakhulu ngumbhobho wentsimbi engenamthungo, kwaye indlela enkulu yeoli ibekwe. Uqhagamshelo lombhobho uqhagamshelwe yi-SAE Flonge kangangoko kunokwenzeka. Luhlobo lwe-bowt ye-blulling ngesiphumo se-welding elungileyo kwaye sisombulula ngokufanelekileyo ingxaki yokuvuza ioyile ebangelwa kukungasebenzi kakuhle.