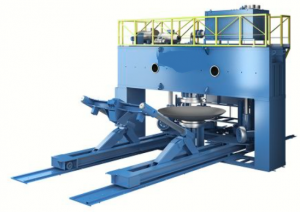

I-800t ejulile yokudweba okujulile kwe-hydraulic Press nge-Work Workbench

1. Uhlaka olukhulu:

Umzimba womshini we-hydraulic wohlobo lwe-hydraulic yisakhiwo sohlaka oluhlanganisiwe, olwakhiwe ngezinsimbi ze-weldive ehleliwe, enamathelayiyini eseceleni eshiywe phakathi kwezinsika ze-welf kanye neyakwesokudla, usebenzisa i-Q355B ephezulu ye-welding sakhiwo, i-carbon dioxide igesi evikelekile; Ngemuva kokufudumala, kudinga ukudlula ekwelashweni okuvelelayo kuqeda ukuguquguquka kwe-welding kanye nengcindezi, kuqinisekiswe ukuthi izingxenye ze-welded zihlala isikhathi eside futhi azilimalanga, futhi ukunemba kuyagcinwa. Ugongolo oluphansi, izinsika, nogongolo olungaphezulu luqiniswa yi-Tie Rods (i-hydraulic ceensing) ukwakha ifreyimu ehlanganisiwe; Kukhona ibhulokhi eshelelayo maphakathi ne-fuselage, futhi ibhlokhi elishelelayo liqondiswa yi-wedge-hlobo Rail Corner and Octagonal Guide Rail, futhi ipuleti lomhlahlandlela we-sliding block lenziwe nge-A3 + Cupb10sn10 impahla ye-A3 +

I-①Upper ugongolo futhi ugongolo olungezansi: ugongolo olungenhla kanye nogongolo olungezansi lubhalwe yiplanethi yensimbi ye-Q355B, futhi ukucindezelwa kwangaphakathi kuqediwe ngemuva kokuqina kwesakhiwo nokunemba kwemishini uqobo. Umgodi wokufakwa kwe-Cylinder Main uthathwe ngogongolo olungaphezulu. Isilinda se-Hydraulic Cushion kanye ne-hydraulic cushion efakiwe ngaphakathi kogongolo olungezansi.

Insika: Insika ifakwe ipuleti yensimbi ye-Q355B, ngemuva kokushiswa, ukwelashwa kosizo kwengcindezi kwenziwa. Iviki lomhlahlandlela wokuguquguquka we-sliding block lifakiwe ngensika.

I-③Tie Rod kanye ne-Lock Nut: okuqukethwe kwenduku ye-Tie kanye ne-Lock Nut yi-45 # STEM. Induku ye-Tie ifaniswe nentambo yokukhiya kwabesifazane futhi iqiniswa ngaphambili yi-Ultra-High Pressure Pressure Pre-Teating depy ukukhiya umzimba.

2. Isilayidi:

Isilayidi yisakhiwo sensimbi enomumo we-welded ebhokisini, futhi iphaneli elingezansi lesilayidi liwucezu lonke lwepuleti yensimbi ukuqinisekisa ukuqina okwanele namandla. Isilayidi sohlobo lwe-hydraulic hlobo lwe-hydraulic sekhava yemoto yemoto yemoto ekwakheka uHlelo lokwamukela ama-cuint okonakele amathathu. Kunamasethi ama-4 amabhlokhi wemihlahlandlela ngakwesobunxele nakwesokudla. Amapuleti womhlahlandlela we-slider ahamba ngokuqondile kujantshi wemihlahlandlela, kanye nokunemba kokuqondisa ukunemba kuncike kujantshi wemihlahlandlela yeslayidi. I-Iron Ethambekele Isetshenziselwa ukujwayela ukuqinisekisa ukufana nokwenziwa kweselula, ukulungiswa okulula, ukunemba okuphezulu okunembe, ukugcinwa kahle kwe-anti-eccentric. Uhlangothi olulodwa lwesiqondisi sesitimela sempikiswano senziwe ngezinto ezibonakalayo ze-alloy, futhi kolunye uhlangothi lwenziwa nge-post-based alloy material. Ngaphezu kwalokho, ujantshi wesiqondisi uqedwe, ngobulukhuni ngenhla kwe-HRC55, ukumelana okuhle nokuphikiswa okuhle kanye nempilo yenkonzo ende. Indawo yesitimela yesilayidi ihlinzekwa ngomgodi othambisayo wokuthambisa okuzenzakalelayo ukuze ugcobe izingxenye ezihambayo. Ukulungiswa okuhle kwesilayidi kutholwa ngokulawulwa kwe-valve ye-Flow Valve ephelele, esetshenziselwa ukulungiswa okuhle ngesikhathi sokukhethwa kwesikhunta ngesikhathi sokukhethwa kwesinqumo sokubumba, futhi kungashintshwa ngaphakathi kwebanga le-0.5-2mm / s.

3. Ukuhambisa i-Workbench Worknch:

I-Frame-Type Hydraulic Press yokwakha izimoto ze-Shell Showell zifakwe ngokuhamba phambili okusebenzayo. Isenzo sokusebenza esishukumisayo yi-Q355B yensimbi ye-Welding Hlathi ye-Q355B. Ngemuva kokufudumala, ukwelashwa kosizo kwengcindezi kwenziwa. Ukusebenza okushukumisayo kucutshungulwa ngama-grooves "t" ama-grooves nama-ejector izimbobo. Ubukhulu be- "T" Groove kanye nomgodi we-ejector pin kwenziwa ngokuya ngomdwebo wesakhiwo onikezwe yi-Party A. Shiya u-400mm phakathi kwe-milling. Ihlotshiswe ngenduku ye-ejector ehambisanayo kanye nesembozo sothuli, ubulukhuni bokushisa lwe-ejector rod ingaphezulu kwe-HRC42 degrees. Ukunemba okuphindaphindwayo kwe-mobile appletable is ± 0.05mm, futhi imodi yokushayela ihloselwe ukuncipha kwejubane, futhi kuyisakhiwo esizihambela. Ngedivayisi efanelekile yokutholwa, lapho igebe phakathi kwendiza engezansi yokusebenza kwendawo yokusebenza kanye nendiza engezansi yogongolo olungezansi lukhulu kune-0.3mm, umgcini awuvunyelwe ukusebenza. Nikeza zonke izembozo ze-mandrel hole. Kukhona isiphambano se-slot slot endizeni ye-Wortable, usayizi ungo-14mm ububanzi kuya ku-6mm ekujuleni.

4. Isilinda esiyinhloko:

Isilinda esiyinhloko samafutha sisebenzisa isakhiwo se-multi-cylinder esihlanganisa isilinda se-piston kanye nesilinda se-plunger. Induku ye-piston yamukela lokhu okusezingeni eliphezulu kwe-carbon ehlekhi yensimbi, kanti ingaphezulu licinyiwe ukukhulisa ubunzima; Umzimba we-cylinder wamukela izikhombisi zensimbi ezisezingeni eliphakeme zekhabhoni ukuze uqinisekise ukufana kwezinto zokwakha, isilinda kawoyela sivalwe ngendandatho yokubopha ephakeme engenisiwe.

5. I-Hydraulic Cushinder Cylinder:

Idivaysi yesilinda ye-hydraulic cushion ifakwa ngaphakathi kogongolo olungezansi kohlobo lwe-hydraulic Press yokwakha ifreyimu yekhava ye-amotobile yomzimba yemoto. I-Hydraulic Cushion inemisebenzi emibili: i-hydraulic cushion noma i-ejector, engasetshenziselwa ukuhlinzeka ngamandla obambele ngenhlanganisela yensimbi noma i-hydraulic cushion inezinzwa zomqhele owodwa, futhi ifakwe inzwa eyodwa yomqhele. Ama-Press angabona kahle ukusethwa kwedijithali kwesikhundla sokuguqulwa kwe-stroke yesilayidi kanye ne-hydraulic cushion, futhi ukusebenza kulula futhi kusebenza.

6. Hambisa okusebenzayo ukuphakamisa isilinda e-clamping:

Ama-cylinder amane aphakamisayo futhi ahlasela amasilinda wohlobo lwe-hydraulic Press yemoto ye-Shetobile Showell Cover ukwakha zonke izakhiwo zohlobo lwe-piston. Zifakwe emgodini ophansi wesiphambano. Ithebula elishukumisekayo lingaphakanyiswa lapho likhuphuka, futhi itafula elishukumisekayo lingaboshwa lapho kwehliswa. Ngaphezulu komshini ophansi.

7. I-Buffer Cylinder:

Idivaysi yokubhoboza ye-punching ilungiselelwe njengoba kudingeka, ehlanganiswa isilinda se-buffer, uhlelo lwe-buffer kanye nendlela exhunyiwe, futhi ifakwe engxenyeni engenhla yomshini wokucindezela onqenqemeni, ukubhoboza kanye nezinye izinqubo zokubhoboza. I-Buffer Cylinder ne-Buffer System angadonsa ukushaqeka futhi aqede ukudlidliza ngesikhathi senqubo yokubhoboza.