Ama-Speent-Colomum Depining Predralic Press ngokuhamba asebenza

Ikholomu engu-4umshini wokudweba ojulile wokudwebaIlungele kakhulu izinqubo zensimbi yensimbi eshidi efana nokwelula, ukugoba, ukumboza, ukwakha, ukubhoboza, ukubhoboza, ukulungiswa, ikakhulukazi kusetshenziselwa ukunwebeka okusheshayo kwensimbi.

Umshini we-Press uklanywe njengoba kubumbene ne-H-Framed enobuqili uhlelo oluhle kakhulu, ukunemba okuphezulu, isikhathi eside impilo nokuthembela okuphezulu, futhi kusetshenziselwa ukucindezela ukukhiqizwa kwensimbi / ngosuku.

I-WhatsApp: +86 176 0282 8986

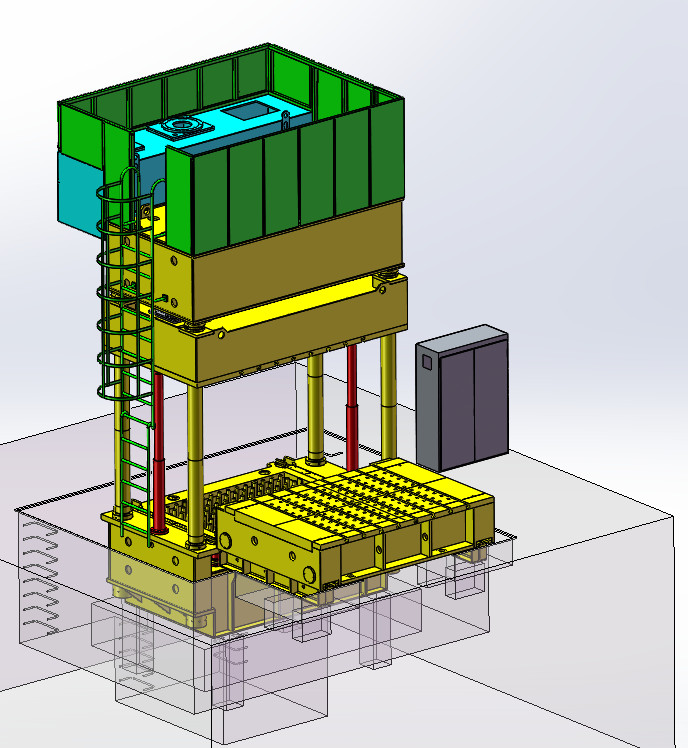

Umdwebo we-3D

Amapharamitha womshini

| Ibizo | Umuvo | Thanda | Thanda | Thanda | Thanda | |

| Isifanekiso |

| Yz27-1250t | Yz27-1000t | Yz27-800t | Yz27-200t | |

| Ingcindezi yesilinda esemqoka | KN | I-12500 | 1000 | I-8000 | 2000 | |

| I-Die Cushion Force | KN | 4000 | 3000 | 2500 | 500 | |

| UMax. Ingcindezi ewuketshezi | I-MPA | 25 | 25 | 25 | 25 | |

| Ukukhanya kosuku | mm | I-2200 | I-2100 | I-2100 | Oku-1250 | |

| Isigaxa esikhulu se-cylinder | mm | I-1200 | I-1200 | I-1200 | 800 | |

| Die cushion stroke | mm | 350 | 350 | 350 | 25 | |

| Usayizi ongasebenzi

| LR | mm | 3500 | 3500 | 3500 | I-2300 |

| FB | mm | Oku-22 | Oku-22 | Oku-22 | 1300 | |

| Usayizi we-die cushion | LR | mm | 2620 | 2620 | 2620 | Umuntu olekayo |

| FB | mm | Umuntu olekayo | Umuntu olekayo | Umuntu olekayo | I-1070 | |

| Isivinini sesilayidi | Ngaphansi | mm / s | 500 | 500 | 500 | -Mashumi |

| Buyisela emuva | mm / s | 300 | 300 | 300 | I-150 | |

| Ukusebenza | mm / s | 10-35 | 10-35 | 10-35 | 10-20 | |

| Ijubane le-Ejeva | Iphuphayo | mm / s | 55 | 55 | 55 | 50 |

| Buyisela emuva | mm / s | 80 | 80 | 80 | 60 | |

| Ibanga elishukumisayo elisebenzayo | mm | Oku-22 | Oku-22 | Oku-22 | 1300 | |

| Umthwalo We-Workbench | T | 40 | 40 | 40 | 20 | |

| Servo motor

| Kw | 140 | 11 | 80 + 18 | 22 | |

| Isisindo somshini | T | 1350 | 11 | 90 | 20 | |

Iphrojekthi efanayo

Isicelo

Umzimba oyinhloko

Umklamo womshini wonke wamukela design activikition complization futhi uhlaziya ngento esemncane. Amandla nokuqina kwemishini kulungile, futhi ukubukeka kukuhle.

Isilinda

| Izingxenye | Fukwekwakha |

| Umphongolo wesilinda | Yenziwe ngensimbi engu-45 # yensimbi ekhethiwe, ecijile nokufutheka

Ukugaya okuhle ngemuva kokugoqa |

| I-Piston Rod | Yenziwe ngensimbi engu-45 # yensimbi ekhethiwe, ecijile nokufutheka Ingaphezulu liyagingqikala bese i-chrome-plated ukuqinisekisa ubulukhuni obungaphezulu kwe-HRC48 ~ 55 Ubulukhuni v.8 |

| Izimpawu | Indandatho yekhwalithi yaseJapan Nok |

| Ipistoni | Iqondiswa yiplizwa yethusi, ukumelana okuhle, ukuqinisekisa ukusebenza kwesikhathi eside kwesilinda

|

Uhlelo lwe-servo

I-1.Servo System Ukwakheka

Ukwakheka kohlelo lwe-2.Servo

| Ibizo | Mumenzi | Picebo | Aukunquma ngqo |

| I-HMI | Nokia |

| Impilo yenkinobho ihlolwe ngokuqinile, futhi ayilimali ngokucindezela izikhathi eziyi-1 million. Usizo lwe-Screen and Machine Fake, chaza imisebenzi yesikrini, chaza ama-alamu womshini, futhi usize abasebenzisi ngokushesha ukuba basebenzise ukusetshenziswa komshini

|

| Ibizo | Mumenzi | Picebo | Aukunquma ngqo |

| I-PLC | Nokia |

| Umugqa wokutholwa kwe-elekthronikhi uyacutshungulwa ngokuzimela, ngekhono elinamandla lokulwa nokuphazamisa Ukulawulwa kwedijithali kwe-servo drive kanye nokuhlanganiswa ne-drive |

| I-Servo Driver

| I-Yaskawa |

| I-capacitor yebhasi ephelele ithuthukiswa ngokuphelele, futhi i-capacitor enokuguquguquka kwezinga lokushisa okubanzi kanye nokuphila kwenkonzo ende kuyasetshenziswa, futhi impilo yethiyori inyuswa ngamahlandla ama-4;

Impendulo ku-50MPA yi-50ms, ingcindezi ngokweqile i-1.5kgf, isikhathi sokuthola ingcindezi singama-60ms, kanye nokuguquguquka kwengcindezi kungu-0.5kgf.

|

| Servo motor

| Isigaba Series |

| Idizayini ye-Simulation yenziwa yi-software ye-Ansoft, futhi ukusebenza kwe-electromagnetic kuphakeme; ukusebenzisa okuphezulu kwe-NDFEB ukuthokozela, ukulahleka kwensimbi kuncane, ukusebenza kahle kuphezulu, futhi ukushisa kuphakeme;

|

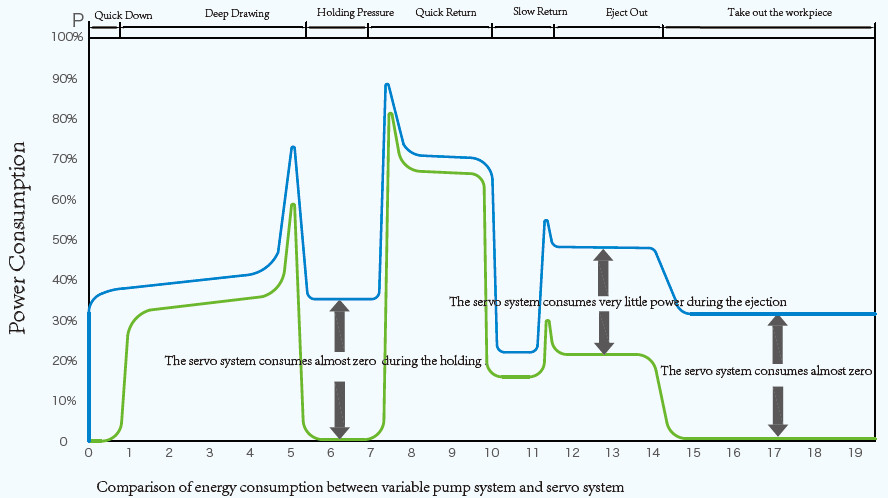

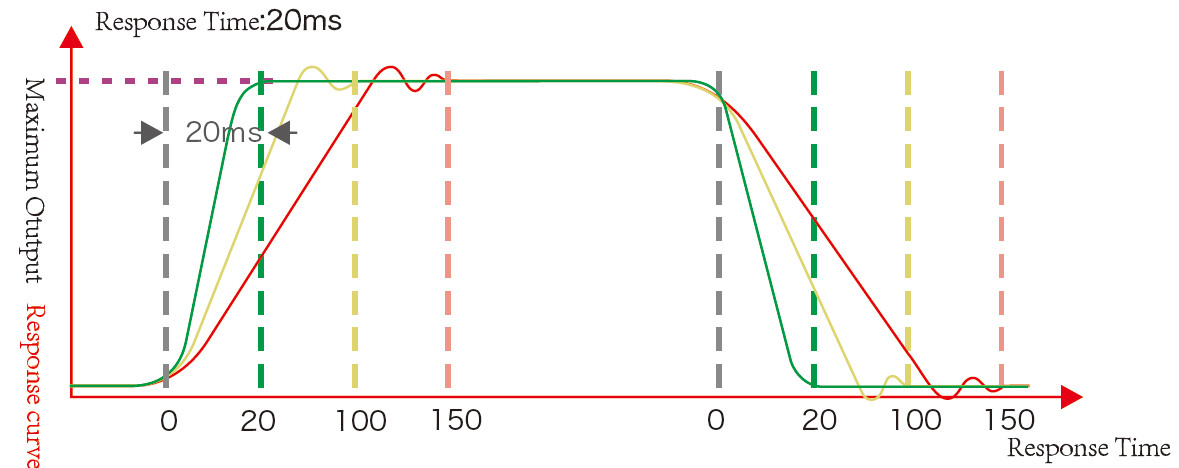

3.Advations of servo system

Ukonga amandla

Uma kuqhathaniswa nohlelo lwempompo yendabuko oluhlukile, uhlelo lwe-servo oil Pump luhlanganisa izici zomthetho wejubane olusheshayo lwemoto ye-servo motor kanye nezimpawu zokuzilawula zamafutha we-hydraulic, okuletha amandla amakhulu wokonga amandla, namandlaisilinganiso sokonga singafinyelela kuma-30% -80%.

-Qeqesheka

Ijubane lokuphendula lishesha futhi isikhathi sokuphendula sifushane ngokuthi ama-20ms, athuthukisa ijubane lokuphendula lohlelo lwe-hydraulic.

Ukwenza kahle

Isivinini sokuphendula esisheshayo siqinisekisa ukunemba okuvulwa nokuvala, ukunemba kwesikhundla kungafinyelela ku-0.1mm, futhi ukunemba okukhethekile kokufika kwesikhundla kungafinyelela± 0.01mm.

Ukunemba okuphezulu, imoduli ye-PID algorithm ephezulu iqinisekisa ingcindezi yesistimu ezinzile nokuguquguquka kwengcindezi kokuncane± 0.5 Bar, Ukwenza ngcono umkhiqizo.

Ukuvikelwa Kwezemvelo

Umsindo: Umsindo ojwayelekile wohlelo lwe-hydraulic servo lungu-15-20 db oluphansi kunalokho kwephampu yoqobo eguquguqukayo.

Ukushisa: Ngemuva kohlelo lwe-servo lusetshenziswa, izinga lokushisa likawoyela le-hydraulic lincishisiwe liphelele, elithuthukisa impilo ye-hydraulic seal noma yehlise amandla okuphola.

Idivaysi yokuphepha

I-Photo-Electrical Safety Guard yangaphambili & emuva

Slide ukukhiya e-TDC

Ukuma kwesandla ezimbili

I-Hydraulic Support Insurance Insurance Insurance

Ukuvikelwa okugcwele ngokweqile: I-valve yezokuphepha

I-Liquid Level Alarm: Izinga lamafutha

Isexwayiso sokushisa samafutha

Ingxenye ngayinye kagesi inokuvikela ngokweqile

Amabhlokhi okuphepha

Ukukhiya amantongomane ahlinzekwa izingxenye ezinyakazayo

Zonke isenzo ze-PRESS zinomsebenzi wokuphepha kokuphepha, isib I-Slide ayikwazi ukucindezela lapho kusebenza ukusebenza kahle. Lapho ukusebenza kwezingxabano kwenzeka, i-alamu ikhombisa esikrinini sokuthinta bese ikhombisa ukuthi yini ingxabano.

Uhlelo lwe-hydraulic

Ubuso

Ithangi le-1.Ix setha uhlelo lokuhlunga olupholile oluphoqelelwe (idivaysi yezimboni yepuleti-hlobo lwamanzi, ukupholisa ngokujikeleza kwamanzi, lokushisa lamafutha ℃, qiniseka ukuthi umshini ucindezele ngokuqinile emahoreni angama-24.)

2.Uhlelo lwe-hydraulic amukele uhlelo lokuhlanganisa i-cartridge valve control system ngejubane lokuphendula okusheshayo nokusebenza kahle kokudluliswa okuphezulu.

3.Ithangi lamafutha lihlome ngesihlungi somoya ukuxhumana ngaphandle ukuze uqinisekise ukuthi amafutha e-hydraulic awangcolisiwe.

4.Ukuxhumana phakathi kwe-valve yokugcwalisa kanye nethangi likaphethiloli kusetshenziswa okuhlangene okuguquguqukayo ukuvikela ukudlidliza kusuka ekutholeni ithangi likaphethiloli futhi uxazulule ngokuphelele inkinga yokuvuza kawoyela.