Ukubanda Kwakha Ama-Hydraulic Press

| |

| |  |

| TOuchisihenqo sebhayisikobho | WI-Orktable |

Isicelo

|  |

I-5000tUkubanda Kwakha Ama-Hydraulic Press, ikakhulukazi isetshenziselwe ukungeniswa kwembiza engezansi, imbiza enganamatheli. Ngaphansi kwengcindezi, cindezela izinsimbi ezimbili ndawonye. Imbiza ephansi kabili othintana nesendlalelo somthombo wokushisa futhi idlulisela ukushisa ngokushesha, okungenza ukuthi kube nomfaniswano wokutshala nokushisa. Ungqimba ngaphakathi kwembiza lubushelelezi, olungamelanayo, alunakulula ukugqwala, futhi ngeke lukhiqize amakhompiyutha alimazayo empilweni yabantu

Izici ezibalulekile

1.Uhlaka luyizinhlaka zohlaka lwe-welded, isimo se-Force sinengqondo, isici sokuphepha sokuklama siphezulu, futhi impilo yenkonzo ingafinyelela ngaphezu kweminyaka eyi-15.

2.Ngaphansi komthwalo ogcwele, ukungaguquki kwetafula kungu-0. 5 ~ 1mm / m, ukuqinisekisa ukucindezelwa okuphezulu okuphezulu.

3.Isilinda esiyinhloko samukela ubuchwepheshe bokubekwa uphawu kwama-anti-anti-ukuvuza kwamazwe omhlaba kanye nobuchwepheshe bensimbi yokunwetshwa kwendandatho, okungathuthukisa kakhulu impilo ethembekile yophawu lwesilinda.

4.I-Cylinder Piston yamukela ubuchwepheshe obuthuthukile be-bimetal welding Ubuchwepheshe, obuthuthukisa ukumelana nokugqoka kanye nempilo ethembekile yesilinda, futhi impilo yenkonzo ingafinyelela izikhathi ezingaphezu kuka-30,000,000.

5.Ubuchwepheshe be-cylinder osheshayo buyakwazi ukubona amandla futhi okusheshayo phansi, ngcono ukusebenza kahle komsebenzi bese ugcine amandla.

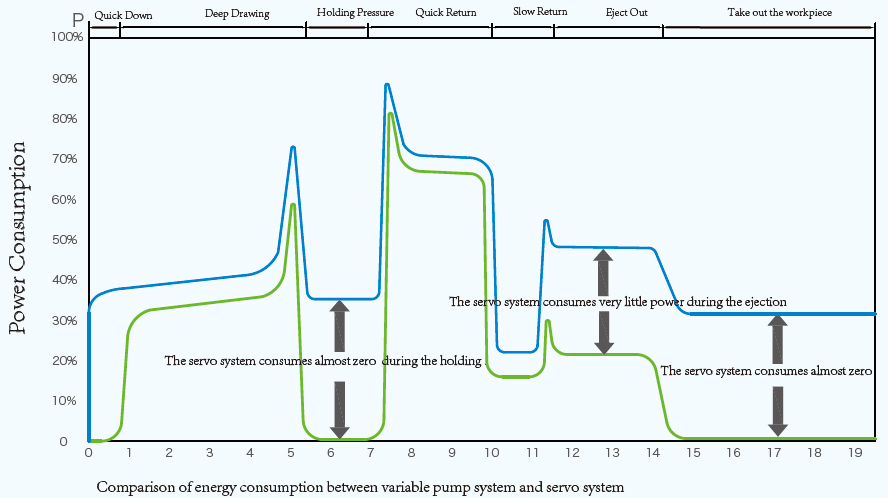

6.Uhlelo lwe-Servo Amafutha Pump luhlanganisa izici zomthethosivivinywa zejubane olusheshayo lwemoto ye-servo kanye nezici zokuzilawula uwoyela izici zephampu ye-hydraulic, futhi isilinganiso sokugcina amandla singafinyelelaKufika kuma-30% -80%.

Ishidi le-data

| No | Ibizo | Ipharameter | ||

| 1 | Isifanekiso | Yz61-5000t | ||

| 2 | Amandla okukho | 50000kn | ||

| 3 | Ingcindezi Yomsebenzi We-Hydraulics, MPA | 80 | ||

| 4 | Cindezela I-Plate Material | Insimbi | ||

| 5 | Isigaxa esikhulu se-cylinder | I-350mm | ||

| 6 | Ukukhanya kosuku | 1100mm | ||

| 7 | Isilinda esiyinhloko qty | 1 | ||

| 8 | Uhlobo lwefreyimu | Isakhiwo sohlaka | ||

| 9 | Ukuphoqelelwa kwe-Ejection | 500Ky | ||

| 10 | Ukushaywa kwe-Eject | 0 ~ 350mm | ||

| 11 | Servo motor | 60 * 3 | ||

| 12 | Ukuphakama okuphezulu kwepuleti | 200mm / sec | ||

| 13 | Ijubane lokuvala ipuleti | 200 mm / sec | ||

| 14 | I-Plate Working Speed | 4.8-19mm / Sec | ||

| 15 | Isisindo somshini | 70 | ||

|

16 | Usayizi ongasebenzi | I-LR | I-1250mm | |

| Isithombe | I-1250mm | |||

|

17 | Ubukhulu | LR | I-3380 | |

| FB | 1980 | |||

| H | I-4390 | |||

Izakhi zezinhlelo

● Umshini we-Hydraulic Press unesakhiwo sohlobo lwezinhlobo owakhelwe ngaphakathi futhi sakhiwe ngomshini omkhulu kanye nendlela yokulawula. Imishini iqukethe uhlaka lonke, uhlelo lukagesi, uhlelo lwe-hydraulic.

● Indlela yokulawula yakhiwa uhlelo lwe-hydraulic, uhlelo lokulawula ugesi, idivaysi ekhawulelwe stroke, amapayipi, ibhokisi lokulawula ugesi nezinye izingxenye ezisizayo. Uhlelo lukagesi kanye nesiteshi se-Hydraulic sixhumeke sibe munye ngamapayipi kawoyela kanye nezintambo zokuhola ukuqaphela inqubo yezenzo zonke.

● Umzimba oyinhloko wesilayidi yipuleti yensimbi engu- # 45 yensimbi. Ipuleti elingezansi lesilayidi yipuleti lensimbi lonke liqinisekisa ukuqina okwanele namandla. Ukuholwa kwesilayidi kuyisitayela se-sideling sedge esine-Foursquare kanye ne-Eight Friction Caide Guide Rail, enikeza ukunemba okuphezulu nokuqina. Ngemuva kokulungiswa, akukho mehluko oqondile owenzeka, ukunemba kugcinwa kahle futhi amandla okumelana umthwalo aqinile, ukuqinisekisa ukucaciswa kokusebenza kwesilayidi, ukuthi isilayidi singamelana nomthwalo omkhulu ngaphandle kwengxoxo. Isigamelwano seSiqondisi ngokuyisilayidi senziwa ngeCopper-Base Alloy, samukele ukwakheka kwamafutha omfula ukuze uqiniseke ukuthi uwoyela wesitimela umhlahlandlela akukho ukuvuza, kukhuphule amandla anakalisayo okuvuzayo. Ku-Guide Rail Kunezimbobo ezikhethekile zokugcwalisa kawoyela zokugcwalisa kawoyela ngokuzenzakalela, ngaphansi kwalapho kukhona i-Oyili Yokuthola ibhokisi ukuvikela u-Oyili Stain phansi.

Uhlelo lokulawula i-Hydraulic

● Uhlelo lokulawula i-Hydraulic lubekwe luhlangothini lwemishini, lapho kwaklanywa khona ipulatifomu yokulondolozwa, ukubukeka okuhle futhi kulula ukukugcina. Uhlelo lwe-hydraulic luqukethe ithangi likawoyela, uhlelo lokulawula oluyinhloko lweHydraulic, isiteshi samaphampu, igeji yokucindezela, i-strainer nezinye izinto. Zixhumeke ohlelweni lonke lokulawula i-hydraulic ikakhulukazi ngamapayipi.

● Uhlelo lwe-hydraulic lubonakala ikakhulukazi ngokulawulwa okusondelene nokuvalwa kwe-servo, Ukulawulwa kokuvikelwa kokusekelwa okubili, njll.

● Ithangi lamafutha setha uhlelo lokuhlunga lokupholisa oluphoqelelwe (idivaysi yezimboni yeplate-uhlobo lwamanzi wokupholisa amanzi, ukupholisa ngokujikeleza kwamanzi, izinga lokushisa lamafutha≤55℃,qiniseka ukuthi umshini ucindezela ngokuqinile emahoreni angama-24.) Ukuqinisekisa ukuthi izinga likawoyela lilawulwa kuhlu oluvumelekile. Uhlobo lokuvikelwa kwamafutha okushisa: uwoyela ufinyelela ku-40℃, isexwayiso sokushisaKuvela esikrinini sokuthinta, uhlelo lokupholisa oluphoqelelwe ukusebenza ngokuzenzakalelayo. Amafutha afinyelela ku-55℃, motor vala phansi, ukumiswa kokusebenza, isexwayiso sokushisa sivela esikrinini sokuthinta.

● Ingcindezi yesilayidi ilawulwa ngokusebenzisa i-valve yengcindezi ebanzi kanye ne-valve ye-bressve elungiselelwe ukude; 2 Imodi ingashintsha ngokukhululeka. (Idivaysi yokusheshisa kanye nokukhohlisa kwe-servo control Pressure kanye nokuguquguquka kokuhamba kufakwa ohlelweni, okungathuthukisa kangcono ukuqina kokuqina kwengcindezi.) Ingcindezi kwimodi yokulawula engxenye ye-Presiction isethwe futhi ikhonjiswe ngqo esikrinini sokuthinta. Ukucaciswa kokuqonda kwengcindezi kungu-0.1mpa, kanye nokucaciswa kokulawulwa kwengcindezi kungaphansi kwe- ± 0.3MPA.

Uhlelo lwe-servo

Ukwakheka kohlelo lwe-servo

Ukonga amandla

Uma kuqhathaniswa nohlelo lwempompo yendabuko oluhlukile, uhlelo lwe-servo oil Pump luhlanganisa izici zomthetho wejubane olusheshayo lwemoto ye-servo motor kanye nezimpawu zokuzilawula zamafutha we-hydraulic, okuletha amandla amakhulu wokonga amandla, namandlaisilinganiso sokonga singafinyelela kuma-30% -80%.

Uhlelo lwe-servo

I-Photo-Electrical Safety Guard yangaphambili & emuva

Ukuma kwesandla ezimbili

Ukukhiya amantongomane ahlinzekwa izingxenye ezinyakazayo

I-Hydraulic Support Insurance Insurance Insurance

Ukuvikelwa okugcwele ngokweqile: I-valve yezokuphepha

I-Liquid Level Alarm: Izinga lamafutha

Isexwayiso sokushisa samafutha