I-Anti-Theft Door embossing hydraulic Press

Icala Lenkampani

Isicelo

Lo mshini ulungele ikakhulukazi ukuthumba umnyango wensimbi. Imishini inokuqina okuhle kohlelo nokunemba okuphezulu, impilo ephezulu kanye nokwethenjwa okuphezulu. Inqubo ethobisayo yezingxenye zensimbi eshidi ihlangabezana nokukhiqizwa kwe-Shifts / Day ..

Amapharamitha womshini

| Ibizo | Umuvo | Thanda | Thanda | Thanda | Thanda | |

| Isifanekiso |

| Yz91-4000t | YZ91-3600T | Yz91-2500t | Yz91-1500t | |

| Force Main Cylinder Force | KN | 40000 | I-36000 | I-25000 | I-15000 | |

| Ukukhanya kosuku | mm | 500 | 500 | 500 | 500 | |

| Isigaxa esikhulu se-cylinder | mm | 400 | 400 | 400 | 400 | |

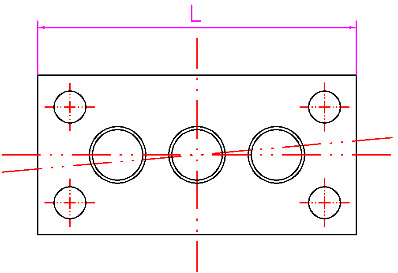

| Cylinder qty. | / | 6 | 6 | 6 | 6 | |

| Usayizi wethebula

| LR | mm | I-1600 | I-1600 | 1400 | 1400 |

| FB | mm | I-2600 | I-2600 | 2400 | 2400 | |

| Isivinini sesilayidi | Ngaphansi | mm / s | I-80-120 | I-80-120 | I-80-120 | I-80-120 |

| Buyisela emuva | mm / s | 100 | 100 | 100 | 100 | |

| Ukusebenza | mm / s | 10-15 | 10-15 | 10-15 | 10-15 | |

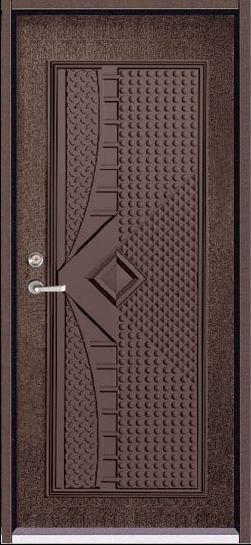

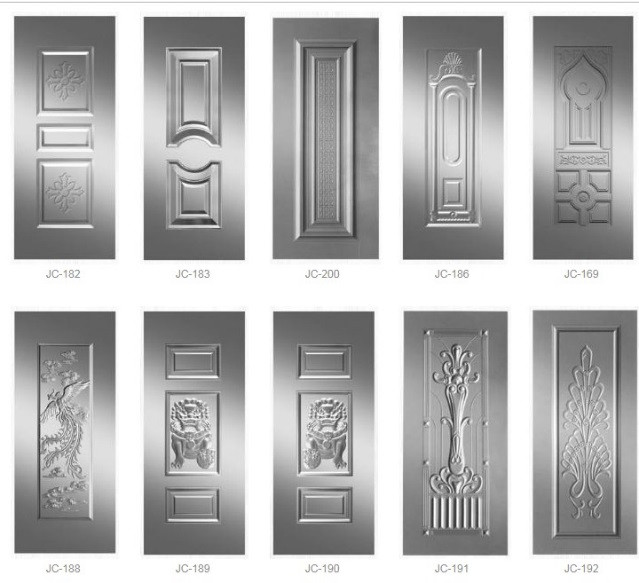

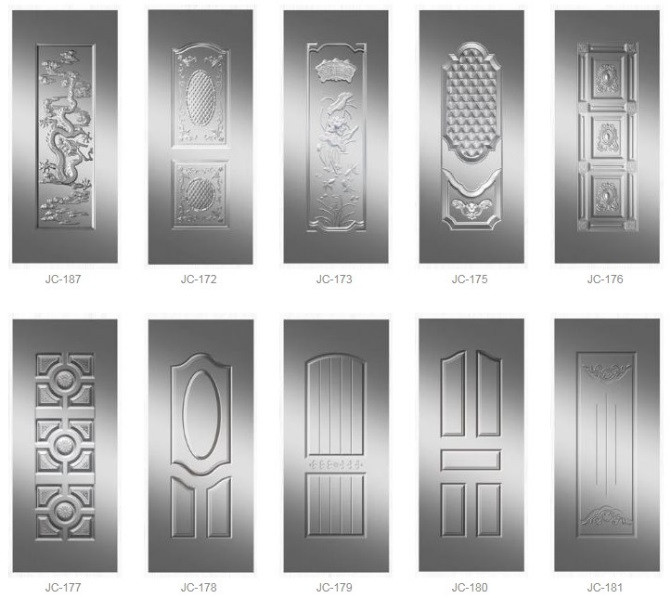

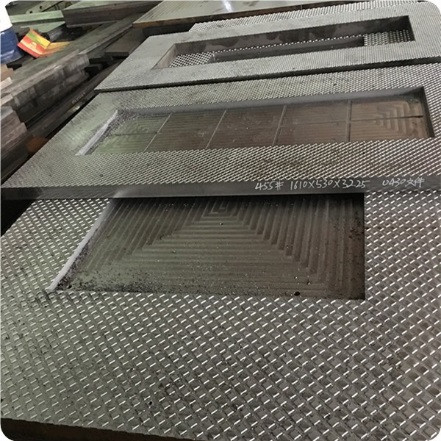

Isikhunta Neminyango

Singanikeza amaphethini ahlukile kumakhasimende okufanele akhethe, singanikeza isikhunta. Isikhunta sizohlolwa efektri yethu.

Isikhunta siqukethe i-1 Iqoqo lokubumba kanye namasethi amaningi wokubumba ama-cores, amakhasimende angenza iphethini ehlukile, futhi adinga kuphela ukuthenga isethi eyi-1 yohlaka lokubumba.

Idivaysi yokuphepha

I-Photo-Electrical Safety Guard yangaphambili & emuva

Slide ukukhiya e-TDC

Ukuma kwesandla ezimbili

I-Hydraulic Support Insurance Insurance Insurance

Ukuvikelwa okugcwele ngokweqile: I-valve yezokuphepha

I-Liquid Level Alarm: Izinga lamafutha

Isexwayiso sokushisa samafutha

Ingxenye ngayinye kagesi inokuvikela ngokweqile

Amabhlokhi okuphepha

Ukukhiya amantongomane ahlinzekwa izingxenye ezinyakazayo

Zonke isenzo ze-PRESS zinomsebenzi wokuphepha kokuphepha, isib I-Slide ayikwazi ukucindezela lapho kusebenza ukusebenza kahle. Lapho ukusebenza kwezingxabano kwenzeka, i-alamu ikhombisa esikrinini sokuthinta bese ikhombisa ukuthi yini ingxabano.

Uhlelo Lokulawula Ugesi

1. Uhlelo lukagesi luqukethe umjikelezo wesekethe lamandla nokulawula umjikelezo. I-Power Circuit ingu-380V, 50hz, obhekele ukuqala, ukuyeka nokuvikela imoto yepompo kawoyela. Uhlelo lokulawula ukulandelela lusebenzisa isilawuli se-PLC esihlelekile esihlanganiswe nesilawuli esikhulu sokuthinta ukubona imijikelezo yenqubo ehlukahlukene yesenzo sethuluzi lomshini.

2. Izingxenye eziphambili zokulawulwa kwamandla okusabalalisa zifakiwe kwikhabethe eliphambili lokulawula, kanye nekhabethe eliphambili lokulawula libekwe emhlabathini ngakwesokunene se-fuselage; Izakhi zokubulawa kwezinto zokusebenza zixhunywe izintambo ezithambile, izitolo eziphambili zeKhabhinethi zivamile, futhi imigqa yokulawula ixhumeke ngama-plug-ins ezindiza ukuze kube lula ukuhlukaniswa nge-averhal.

I-3. Umsebenzi oyisisekelo wengxenye yokulawula uthathwa ngumlawuli we- "PLC" ohlelekile ohlelekile. Ngokwezidingo zenqubo, imiyalo ekhishwe yizinto eziphambili zokulawula (ukushintshwa kokukhethwa, izinkinobho, njll.), Kususelwa kumanani we-analog, njll. I-Actuator-Cylinder, bese uqedela inqubo yokukhiqiza yomshini.

I-Stroke yesilayidi ilawulwa inzwa enokuthula ngokuphelele. I-sensor ephuma emfuleni ihlelwe engxenyeni engenhla yengaphakathi lekholomu. Iphuzu lokuguqulwa lokuguqula isikhundla lingasethwa ngqo futhi liboniswe esikrinini sokuthinta. Ngaphezu kwalokho, kukhona ukushintshwa komkhawulo okuphezulu nangaphansi kokuvikelwa okuphindwe kabili ezimweni ezingalindelekile.

I-4. Iphaneli yokulawula ukusebenza okuphakathi kwemishini ihlelwe kwikhabethe eliphambili lokulawula, kanye nesikrini sePhaneli Yezimboni Yezimboni, ukushintshwa kwesikhombi sokusebenza kanye nokukhethwa kwezindawo okusebenzayo kanye nokukhethwa kukagesi kuqukethe umjikelezo wesekethe namandla. I-Power Circuit ingu-380V, 50hz, obhekele ukuqala, ukuyeka nokuvikela imoto yepompo kawoyela. Uhlelo lokulawula ukulandelela lusebenzisa isilawuli se-PLC esihlelekile esihlanganiswe nesilawuli esikhulu sokuthinta ukubona imijikelezo yenqubo ehlukahlukene yesenzo sethuluzi lomshini.

Izakhi eziphambili zokulawulwa kwamandla okusabalalisa zifakiwe kwikhabethe eliphambili lokulawula, kanye nekhabethe eliyisisekelo libekwe emhlabathini ngakwesokunene se-fuselage; Izakhi zokubulawa kwezinto zokusebenza zixhunywe izintambo ezithambile, izitolo eziphambili zeKhabhinethi zivamile, futhi imigqa yokulawula ixhumeke ngama-plug-ins ezindiza ukuze kube lula ukuhlukaniswa nge-averhal.

5 Ngokwezidingo zenqubo, imiyalo ekhishwe yizinto eziphambili zokulawula (ukushintshwa kokukhethwa, izinkinobho, njll.), Kususelwa kumanani we-analog, njll. I-Actuator-Cylinder, bese uqedela inqubo yokukhiqiza yomshini.

I-Stroke yesilayidi ilawulwa inzwa enokuthula ngokuphelele. I-sensor ephuma emfuleni ihlelwe engxenyeni engenhla yengaphakathi lekholomu. Iphuzu lokuguqulwa lokuguqula isikhundla lingasethwa ngqo futhi liboniswe esikrinini sokuthinta. Ngaphezu kwalokho, kukhona ukushintshwa komkhawulo okuphezulu nangaphansi kokuvikelwa okuphindwe kabili ezimweni ezingalindelekile.

I-6. Iphaneli Yokulawula Ukusebenza Kwe-Operation Orpect of the Main Control Canethi, kanye nePhaneli Panel Industrial Display Revenual Screen, Ukukhanya kwesikhombisi sokusebenza kanye nezinkinobho zokusebenza ezidingekayo kanye nokukhethwa kokukhetha kuhlelwe kuphaneli.

Uhlelo lwe-hydraulic

Isici:

1≤55℃,qiniseka ukuthi umshini ucindezela ngokuqinile emahoreni angama-24.

2

I-3. Ithangi likawoyela lihlome ngesihlungi somoya ukuxhumana ngaphandle ukuze uqinisekise ukuthi uwoyela we-hydraulic akangcoliswanga.

4. Ukuxhumana phakathi kwe-valve yokugcwalisa kanye nethangi likaphethiloli kusebenzisa ukuhlanganiswa okuguquguqukayo ukuvikela ukudlidliza kusuka ekutholeni ithangi likaphethiloli futhi uxazulule ngokuphelele inkinga yokuvuza kawoyela.

Ukunyakaza Kwezobuchwepheshe

1.Umshini we-Press ungasebenza ngezindlela ezi-4: ukulungiswa (intshi), ibhukwana, elizenzakalelayo elizenzakalelayo elizenzakalelayo, imodi yokusebenza nayo ingahlukaniswa ngezindlela ezi-2: Ukuqalwa kwebanga njalo kanye nokucindezela okuqhubekayo

2. Imodi yebanga njalo:Lapho izikhundla zamanje ze-slide ne-cushion zifinyelela isikhundla esethiwe, umsebenzi wamanje uyamiswa. Inani lebanga eliqhubekayo lama-slides lingaphakathi kohlu lwesilayidi esigcwele unhlangothi.

I-3. Imodi yokucindezela njalo:Lapho izingcindezi zamanje zesilayidi ne-cushion zifinyelela umfutho wokusethiwe, umsebenzi wamanje uyamiswa.

4. Ukulungiswa (intshi):Sebenzisa izinkinobho ezisebenzayo ezisebenzayo ukuqedela izenzo ezihambisanayo. Ukucindezela inkinobho yesikhathi esisodwa kwenza umshini wokucindezela uqede intshi yesikhathi esisodwa. Umshini wokucindezela uyamiswa lapho kukhishwa inkinobho. Le modi isetshenziselwa ikakhulukazi ukuguqula umshini wokucindezela bese ubuyisela okufayo.

5. Ibhukwana:Cindezela inkinobho ngayinye yokusebenza ukuze uqedele isenzo esifanayo, i-push ngayinye ephelele yesenzo.

6. I-SEMI-othomathikhi:Inkinobho yokucindezela ngesandla ephindwe kabili ukuqedela umjikelezo owodwa: lapho kucindezelwa inkinobho ephindwe kabili, umshini wokucindezela ugcwalisa isethi yenqubo yenqubo (inqubo yokujikeleza kufanele isethiwe)

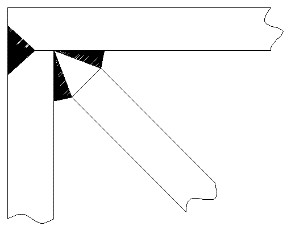

Ukucaciswa kwe-Welding komzimba main

| Uhlobo | I-Tlch | Khipha ku-KB | Buza |

|

| I-A-Side H = T2 / 3 B-Side H = T1 / 3 C≥4 l≤3 | A-side 60 ° B-side 35 ° I-1 / 4≤k≤t | I-Tack-Beld-emangalweni emaceleni yokuqala bese-ke i-Wack-Weld, okokugcina-i-Weld |

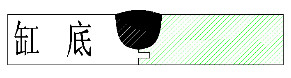

| Isilinda phansi

| Ngokusho komdwebo | Ngokusho komdwebo | I-Tack-Weld Ezinhlangothi Ezinhlangothi ezimbili bese i-wack-Weld, ngemuva kokuvimbela okungama-cosmetic-weld |

| I-A-Side H = T / 2 B-side h = t / 3 C≥4 l≤3 | A-side 60 ° B-side 35 ° 1/4≤k≤10 | I-Tack-Beld-emangalweni emaceleni yokuqala bese-ke i-Wack-Weld, okokugcina-i-Weld |

| I-V-Speaked Groove H = T / 3 C≥4 l≤3 | 40O≤b≤60o 1 / 4≤k≤8 | I-Tack-Beld-emangalweni emaceleni yokuqala bese-ke i-Wack-Weld, okokugcina-i-Weld |

| I-Double-V Groove H = t / 3 C≥4 l≤3 | 40O≤b≤60o 1 / 4≤k≤8 | I-Tack-Beld-emangalweni emaceleni yokuqala bese-ke i-Wack-Weld, okokugcina-i-Weld |

| I-V-Speaked Groove H = T / 3 C≥4 l≤3 | 40O≤b≤60o 1 / 4≤k≤8 | Ukucutshungulwa kwe-T-HASH kufana nenhla, ukushibilika kweplanethi ye-welding ngemuva kokuqedwa kwe-T-shape |

|

| I-V-Speaked Groove H = T2 / 3 C≥4 l≤3 | B≤60o 1/4≤k≤10 | I-Tack-Weld okokuqala ke-keld-webhusayithi, i-cosmetic-wew |

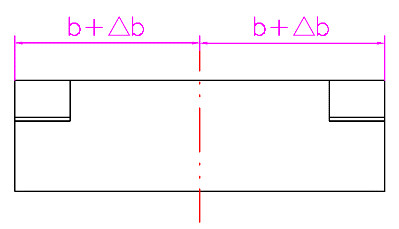

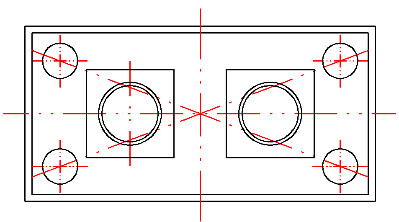

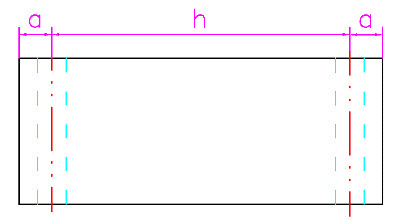

Ithebula lokubekezelela ukwakheka komzimba

| Ukwakheka | Into yendaba | Ukubekezela |

| Ukuvumelanisa kwezinto zangaphandle zesakhiwo se-fuselage(Ukubekezela Ukubekezelela△ bIsihlehlukene | B≤1000 △ B≤1.5 1000 b>2000△ B≤3.0 |

| I-FUSELEGAGE DRAD REXCANILLALAL(I-Diagonal l Ukubekezelelana△ lIsihlehlukene | L≤2000 △ l≤3.0 2000 L>4000△ l≤5.0 |

| Ukufana phakathi kwenhla nangaphansi kwesakhiwo sekholomu t(Ukuthambekela kufaka phakathi amapuleti aphezulu nangaphansiIsihlehlukene | H≤4000 T≤2.0 4000 h>I-8000 T≤5.0 |

| Ukungasebenzi kahle kwamabhodi aphezulu nangaphansi wesakhiwo se-fuselage | L≤2000 T≤2.0 L> 2000 t≤3.0 |

Ukubekezelela i-welding angle

| Khuphuka | Usayizi omfushane onqenqemeni mm | |||

| ≤315 | >315 ~ 1m | >1 ~ 2m | >2m | |

| A | ≤1.5 | ≤2.0 | ≤2.5 | ≤3.0 |

| B | ≤2.5 | ≤3.0 | ≤3.5 | ≤4.0 |

| A | ± 20 ' | ± 15 '' | ± 10 ' | _ |

| B | ± 1 ° | ± 45 '' | ± 30 ' | _ |

Ukubekezelela ukwakheka kwe-welding kanye nesikhundla

| Khuphuka | Ubukhulu obuyisisekelo mm | |||||

| ≤315 | >315 ~ 1 | >1 ~ 2m | >2 ~ 4m | >4 ~ 8m | >8m | |

| A | 1.0 | 1.5 | I-2.0 | I-3.0 | I-4 | I-5 |

| B | I-2.0 | I-3.0 | I-4 | I- | 8.0 | 10.0 |

| C | I-3.0 | I-5 | 9.0 | 11.0 | 16.0 | 20.0 |

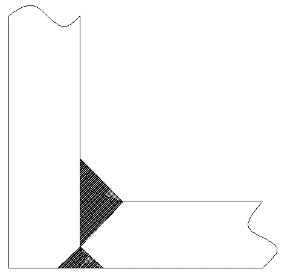

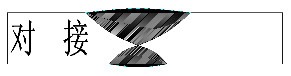

butt ukuhlangana

butt ukuhlangana

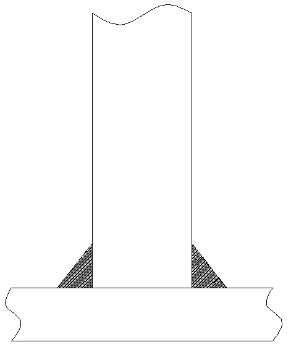

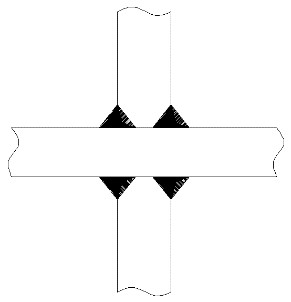

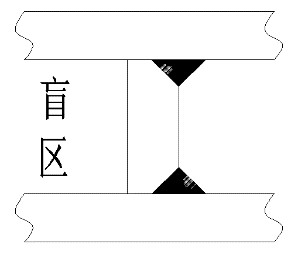

Uzibuzz

Uzibuzz