I-Metal Powder yakha i-Hydraulic Press

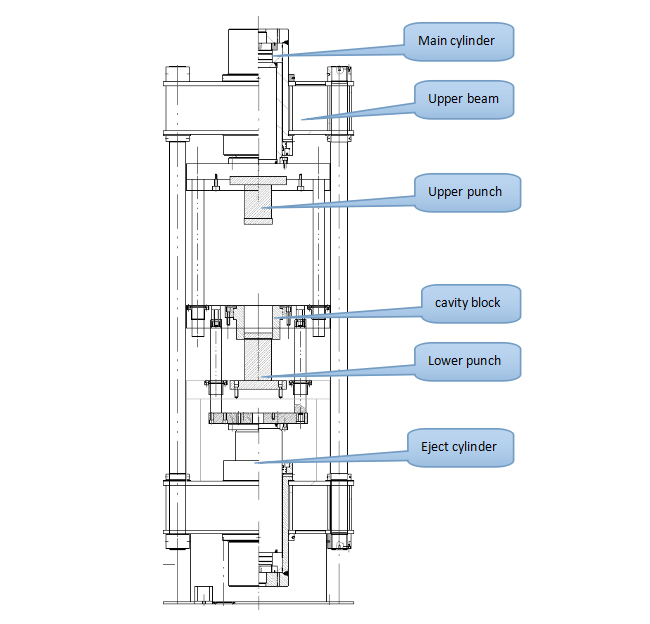

Ifreyimu Yokubumba

1) Isisekelo sokubumba senziwa ikakhulukazi nge-40cr ne-45 # Store ngokuphendula, ukuguqula nokugaya okuhle ukuqinisekisa insimbi eyanele nokuqonda okufanayo. Umhlahlandlela webanga wamukela umehluko wezinto ezibonakalayo ukuvikela ubuso kusuka ku-abrasion, njenge-Copper Guide Sleeve. No-cr.

2) Ingxenye engenhla yokubumba yohlaka lokubumba iyi-punch eyodwa ephezulu, futhi i-punch ephezulu ihlelwe ngokuqondile kwi-slide ye-punch ephezulu; Isikhunta sowesifazane sihlelwe esithenjisweni esingesihle, futhi zombili ukucindezelwa okuntantayo okusebenzayo kanye nokucindezelwa okuntantayo okuphoqelelwe kwenziwa kwinqubo yokucindezela. Kukhethwe ngokunganqikakisi, "Powder", ukucindezelwa okuntantayo, ingcindezi ebambe ukubambezeleka, ukubambezeleka kosizo kwengcindezi, njll. Kungabonakala lapho kucindezela. Lapho uhambisa impuphu, isikhunta esingenhla esiphansi esintantayo siyantanta ngokuvumelanisa nge-punch ephezulu.

I-3) Indlela yokulima inobunzima obujwayelekile nokuvikela ukudilizwa kokukhethwa; Isikhunta sowesifazane kanye ne-undershoot kubhekwe ngasikhathi sinye ukudedela ukukhulula ngokuqondile isikhunta, futhi ukukhululwa okusebenzayo kwesikhunta sowesifazane isikhunta kuyazuzisa ukuvikela umkhiqizo ekulimaleni kalula.

4) Ukuphakelwa kokuphakama, ukuphakama komkhiqizo okuphezulu kanye nesikhundla esidonsayo sebenzisa inzwa yokufudumala yokuthola ukunemba kwesikhundla kanye ne-PLC uhlelo lokulawula uhlelo, kanye nomkhawulo wedivaysi yemishini.

5) Izinto ezingezona ze-composite ezingezona zensimbi zifakwe ekuhlanganiseni phakathi kwepuleti elintantayo kanye ne-cavity block yohlaka lokubumba, kanye nezinto ezingezona zensimbi zihlukaniswe esicathulweni sokudla kanye ne-hopper yesitoreji, futhi zonke izingxenye zensimbi azixhumani ne-powder eluhlaza.

Uhlelo Lokudla

1.Uhlelo lokondla luzoba ne-hoppers engu-6, futhi i-hopper ngayinye izolayisha izinto ezihlukile ezingavuthiwe.

I-HOPPER ingashintshwa, futhi inokuvalwa okuhle.

I-3.Auutomatic Loading yezinto zokwakha, njalo ngemivimbo engu-5-10.

Inani elisebenzayo le-4.hopper lingasetwa kwi-HMI, 1,2,3 ... 10, isebenza ngokubambisana.

5.6 Ama-hoppers amakhulu azofakwa ngaphezulu komshini, i-hopper ngayinye ingalayisha i-15 kg ye-powder.

Insika

Izindlela zokuqondisa (izinsika) zizokwenziwaC45 insimbi evuthayofuthi ube nokuqina okunzima kwe-chrome 0.08mm. Futhi wenze lukhuni nokwelashwa okuvuthayo.

Izindinganiso Zokukhiqiza

JB / T3818-99"Izimo Zobuchwepheshe zeHydraulic Press"

GB5226.1-2002"Ukuphepha kwemishini-imishini kanye nemishini kagesi-ingxenye 1: Izidingo ezijwayelekile zobuchwepheshe"

GB / T 3766-2001"Izidingo zobuchwepheshe ezijwayelekile ze-hydraulic systems"

GB17120-97"Cindezela Izidingo Zobuchwepheshe Bemishini"

JB9967-99"Umkhawulo womculo we-Hydraulic"

Umzimba oyinhloko

Umklamo womshini wonke wamukela design activikition complization futhi uhlaziya ngento esemncane. Amandla nokuqina kwemishini kulungile, futhi ukubukeka kukuhle. Zonke izingxenye zomshini zomshini womshini zifakwe yiplate yensimbi esezingeni eliphakeme yensimbi Q345B, efakwe nge-carbon dioxide ukuqinisekisa ikhwalithi ye-welding.

Isilinda

| Izingxenye | Fukwekwakha |

| Umphongolo wesilinda |

|

| I-Piston Rod |

|

| Izimpawu | Indandatho yekhwalithi yaseJapan Nok |

| Ipistoni | Iqondiswa yiplizwa yethusi, ukumelana okuhle, ukuqinisekisa ukusebenza kwesikhathi eside kwesilinda |

Uhlelo lwe-servo

I-1.Servo System Ukwakheka

I-2.Advages yohlelo lwe-servo

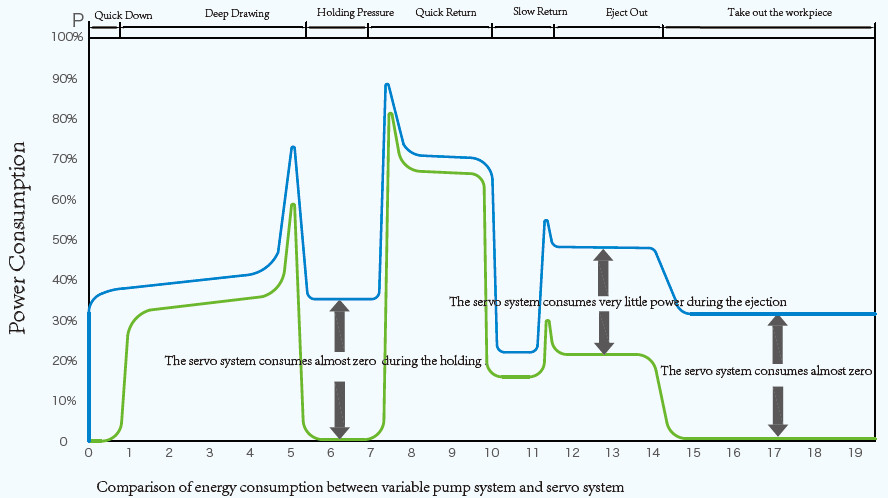

Ukonga amandla

Uma kuqhathaniswa nohlelo lwempompo yendabuko oluhlukile, uhlelo lwe-servo oil Pump luhlanganisa izici zomthetho wejubane olusheshayo lwemoto ye-servo motor kanye nezimpawu zokuzilawula zamafutha we-hydraulic, okuletha amandla amakhulu wokonga amandla, namandlaisilinganiso sokonga singafinyelela kuma-30% -80%.

-Qeqesheka

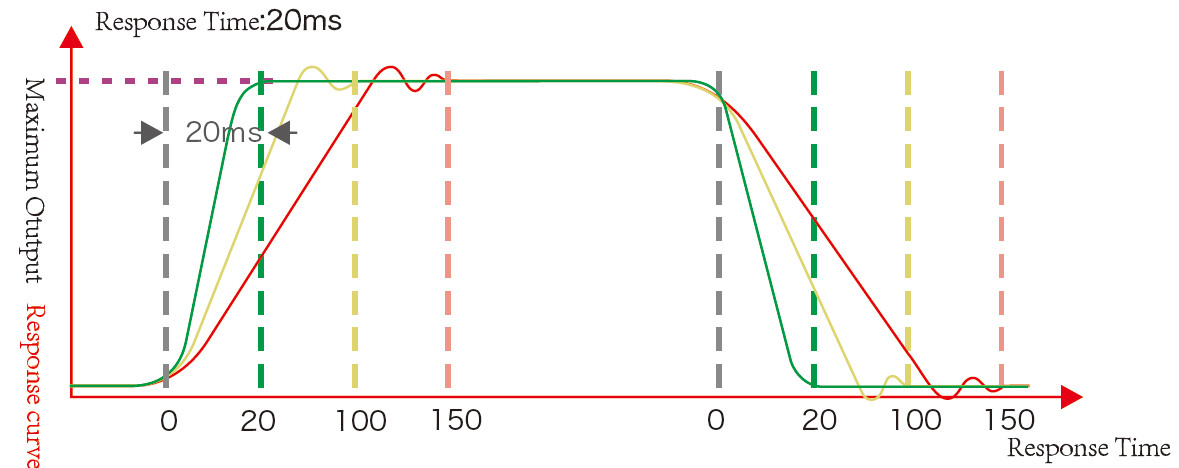

Ijubane lokuphendula lishesha futhi isikhathi sokuphendula sifushane ngokuthi ama-20ms, athuthukisa ijubane lokuphendula lohlelo lwe-hydraulic.

Ukwenza kahle

Isivinini sokuphendula esisheshayo siqinisekisa ukunemba okuvulwa nokuvala, ukunemba kwesikhundla kungafinyelela ku-0.1mm, futhi ukunemba okukhethekile kokufika kwesikhundla kungafinyelela± 0.01mm.

Ukunemba okuphezulu, imoduli ye-PID algorithm ephezulu iqinisekisa ingcindezi yesistimu ezinzile nokuguquguquka kwengcindezi kokuncane± 0.5 Bar, Ukwenza ngcono umkhiqizo.

Ukuvikelwa Kwezemvelo

Umsindo: Umsindo ojwayelekile wohlelo lwe-hydraulic servo lungu-15-20 db oluphansi kunalokho kwephampu yoqobo eguquguqukayo.

Ukushisa: Ngemuva kohlelo lwe-servo lusetshenziswa, izinga lokushisa likawoyela le-hydraulic lincishisiwe liphelele, elithuthukisa impilo ye-hydraulic seal noma yehlise amandla okuphola.

Idivaysi yokuphepha

I-Photo-Electrical Safety Guard yangaphambili & emuva

Slide ukukhiya e-TDC

Ukuma kwesandla ezimbili

I-Hydraulic Support Insurance Insurance Insurance

Ukuvikelwa okugcwele ngokweqile: I-valve yezokuphepha

I-Liquid Level Alarm: Izinga lamafutha

Isexwayiso sokushisa samafutha

Ingxenye ngayinye kagesi inokuvikela ngokweqile

Amabhlokhi okuphepha

Ukukhiya amantongomane ahlinzekwa izingxenye ezinyakazayo

Zonke isenzo ze-PRESS zinomsebenzi wokuphepha kokuphepha, isib I-Slide ayikwazi ukucindezela lapho kusebenza ukusebenza kahle. Lapho ukusebenza kwezingxabano kwenzeka, i-alamu ikhombisa esikrinini sokuthinta bese ikhombisa ukuthi yini ingxabano.

Uhlelo lwe-hydraulic

Ithangi le-1.Ix setha uhlelo lokuhlunga olupholile oluphoqelelwe (idivaysi yezimboni yepuleti-hlobo lwamanzi, ukupholisa ngokujikeleza kwamanzi, lokushisa lamafutha ℃, qiniseka ukuthi umshini ucindezele ngokuqinile emahoreni angama-24.)

2.Uhlelo lwe-hydraulic amukele uhlelo lokuhlanganisa i-cartridge valve control system ngejubane lokuphendula okusheshayo nokusebenza kahle kokudluliswa okuphezulu.

3.Ithangi lamafutha lihlome ngesihlungi somoya ukuxhumana ngaphandle ukuze uqinisekise ukuthi amafutha e-hydraulic awangcolisiwe.

4.Ukuxhumana phakathi kwe-valve yokugcwalisa kanye nethangi likaphethiloli kusetshenziswa okuhlangene okuguquguqukayo ukuvikela ukudlidliza kusuka ekutholeni ithangi likaphethiloli futhi uxazulule ngokuphelele inkinga yokuvuza kawoyela.