Ukukhucululwa okubandayo nokuvutha okushisayo kuyizinqubo ezimbili ezibalulekile ezivamile emkhakheni wezenkolo ezazikhohla. Banomehluko omkhulu eplastikini yezinto ezibonakalayo, izimo zokushisa, i-microskruction, kanye nobubanzi bezicelo. Kulesi sihloko, sizoxoxa ngokuningiliziwe izici zalezi zinqubo ezimbili, kanye nokusetshenziswa kwemishini ebandayo nevuthayo ekukhiqizweni kwangempela.

Umehluko phakathi kokubanda okubandayo nokushisa okushisayo

Ukusolwa okubandayo kubhekisele kwinqubo eyabiwe yenziwa emazingeni okushisa asekamelweni, futhi izinga lokushisa lomsebenzi wensimbi liphansi kunokushisa kabusha kwezinga lokuphindaphinda. Ngenxa yeplastiki elibi lezinto zokwakha emazingeni okushisa aphansi, ukugcwala kubanda kuvame ukudinga amandla amakhulu ukufeza i-deformation yepulasitiki. Ngakho-ke, ukucekela phansi kubanda kulungele izinto zokwakha ze-alloy ngamandla aphezulu. Ukuvuselelwa okushisayo kuyinqubo ebikwe ngaphansi kwezimo zokushisa okuphezulu, futhi izinga lokushisa lomsebenzi wensimbi liphakeme kunamazinga okushisa kabusha. Emazingeni okushisa aphezulu, insimbi ine-plastiki enhle, ngakho-ke ukudala okushisayo kudinga ukufaka amandla amancane, alungele izinhlobo ezahlukahlukene zezinto zensimbi.

Umehluko wokushisa phakathi kokukhulelwa okubandayo nokuvuselelwa okushisayo kunomthelela obalulekile kwisimo salokho okungokwemvelo. Ngesikhathi sokubanda okubandayo, okusanhlamvu kwensimbi akuthambekele ekubunjweni kabusha, ngakho-ke i-morphology yama-grain angempela ivame ukugcinwa ngemuva kokubanda. Enqubweni yokwakha esishisayo, okusanhlamvu kwensimbi kulula ukuwaphindaphinda amazinga okushisa aphezulu, ngakho-ke isakhiwo esilinganiselwe nesinhlamvu esisezingeni eliphezulu sivame ukutholwa ngemuva kokushisa. Ngakho-ke, ukuthethelela okushisayo kungathuthukisa ubulukhuni nobunzima bemisebenzi.

Ngaphezu kwalokho, ukucebisisa okubandayo nokuvuselelwa okushisayo kube namabanga ahlukile ngohlelo lokusebenza olusebenzayo. Ukuqinisekiswa okubandayo kusetshenziselwa ikakhulukazi ukukhiqiza ama-arvices we-alloy ngamandla aphezulu kanye neplastiki ephansi, njengensimbi enamandla. Ngoba umkhuhlane wakha udinga ukusetshenziswa kwamabutho amakhulu, ngokuvamile asetshenziselwa ukwenza imisebenzi emincane futhi enobumba obulula. Ukuvuza okushisayo kulungele izinto eziningi zensimbi. Kungenza ama-WorkPeices ngezimo eziyinkimbinkimbi futhi kungathuthukisa ubunzima nobunzima bezinto zokwakha. Kusetshenziswa kabanzi ekwenziweni kwemishini emikhulu yezimboni efana nezingxenye ze-auto, izingxenye ze-aerospace, nemishini yobunjiniyela.

Umshini obandayo owakhayo nomshini wokuvuselela oshisayo

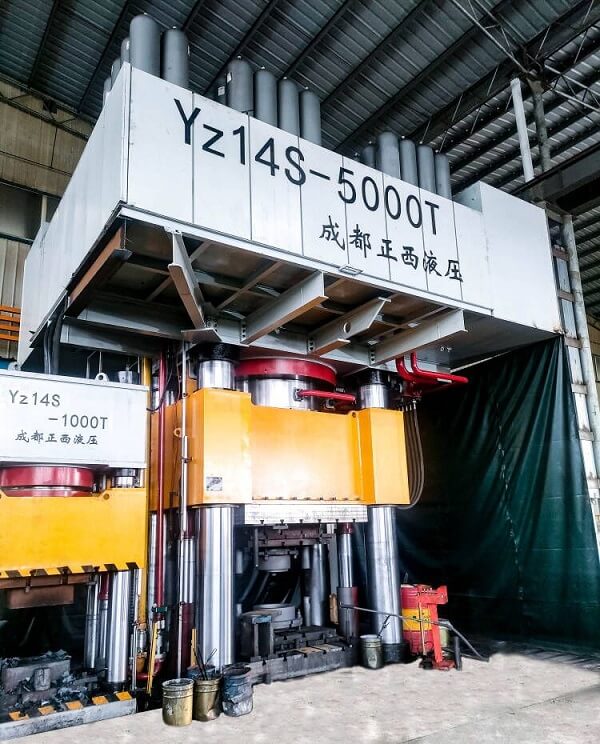

A Umshini Obandayo WokubandaIngabe imishini ekhethekile yenqubo ebandayo yokwakha amandla, isici sayo esiyinhloko ukuthi singakwenza ukufeza insimbi yokushisa egumbini lokushisa. Imishini ebandayo ebandanda ihlanganisa imishini ebandayo ye-hydraulic ebandayo kanye nemishini ebandayo yemishini ebandayo. Umshini wokubanda we-hydraulic obandayo ushayela inqubo yokwakha ngohlelo lwe-hydraulic, olunamandla amakhulu okuvuselela kanye nokuvumelana nezimo futhi angasetshenziswa ukwenza imisebenzi yobungani obuhlukahlukene. Umshini wokubanda omakhalekhayo uqalisa inqubo yokwakha ngokudluliselwa kwemishini. Uma kuqhathaniswa nomshini wokukhalelwa okubandayo we-hydraulic, amandla ayo okubalelwa amancane, kepha anezinzuzo kwezinye izinhlelo ezithile.

Umshini wokuvuselela oshisayo yimishini ekhethekile yenqubo yokuvuselela okushisayo futhi ungafeza izinsimbi zensimbi ngaphansi kwezimo zokushisa okuphezulu. Imvamisa yamukela i-hydraulic noma ukudluliselwa kwemishini. Futhi izinhlobo ezahlukene zemishini zikhethwa ngokuya nge-FACH FACH FACE FORD kanye nezidingo zenqubo. Le khasiUkushisa UkucindezelaFudumeza i-wetal mailpiece ngaphezulu kwendlela yokuphumula yokuphindaphinda ukuze ikwenze ifinyelele kuplastiki enhle bese isebenzisa amandla afanele ukuqedela inqubo yokwakha.

Ekukhiqizweni kwangempela, yomibili imishini ebandayo yokwakha nemishini eshisayo evuthayo idlala indima ebalulekile. Umshini wokukhokhela obandayo ulungele izinto zokwakha ze-alloy ezinezidingo zeplastiki eziphansi kanye nezidingo eziphakeme zamandla. Imvamisa isetshenziselwa ukukhiqiza ama-arganiece asayizi amancane, njenge-bolts, amantongomane, njll. Umshini wokuvuselela oshisayo ulungele izinto zensimbi ezinezidingo eziphakeme ngohlobo lwezinto ezibonakalayo futhi kudingeka uthuthukise ubulukhuni kanye neplastiki. Kungakha ama-Workies amakhulu anosayizi omkhulu futhi obuyinkimbinkimbi, njengezimoto ze-amobile kanye nezingxenye ze-Aero-Injini.

Ukufingqa, ukucebisisa okubandayo nokuvuselelwa okushisayo kuyizinqubo ezimbili ezivamile ekulweni kwezensimbi. Futhi banokwehluka okuphakeme kokushisa, ipulasitiki yezinto ezibonakalayo, i-microssCreature, kanye nobubanzi bokusebenza. Ukwakha amakhaza kufanelekile izinto zokwakha eziphakeme ngamandla aphezulu kanye neplastiki ephansi, ngenkathi ukuvuma okushisayo kulungele izinhlobo ezahlukahlukene zezinsimbi, ikakhulukazi lezo ezidinga ukuthuthukisa ubunzima nobunzima beplastiki. Imishini ebandayo yokwakha nemishini eshisayo evuthayo imishini ekhethekile esetshenziselwa ukufeza lezi zinqubo ezimbili. Badlala indima ebalulekile emkhakheni we-Metal Processing, enikeza izingxenye zensimbi ezisezingeni eliphakeme ezimbonini ezahlukahlukene.

UZhengengxi uyaziwa kahleUmkhiqizi Wokucindezela KwaseChina, ukuhlinzeka ngemishini esezingeni eliphakeme ebukhoma nemishini eshisayo evuthayo. Uma unezidingo, sicela uxhumane nathi ngokushesha. Ochwepheshe bethu bazokunikeza ngezixazululo eziphelele ze-hydraulic cindezela.

Isikhathi sePosi: Aug-04-2023