Isitsha sokuphela siyimbozo sokuphela esitsheni sengcindezi futhi iyingxenye esemqoka yokucindezela komkhumbi wengcindezi. Izinga lekhanda lihlobene ngqo nokusebenza kwesikhathi eside okuphephile nokuthembekile komkhumbi wengcindezi. Kuyinto ebaluleke kakhulu futhi ebalulekile kwi-Prescing Vessel Equipment kuma-petrochemicals, ama-athomu amandla, ukudla, amakhamishini, neminye imikhakha eminingi.

Ngokuya ngesimo, amakhanda angahlukaniswa ngamakhanda aphansi, amakhanda abunjiwe emphushini, amakhanda aval, namakhanda ama-spherical. Amakhanda wemithambo yengcindezi ephezulu nama-boilers amakhanda amaningi ayindilinga, futhi amakhanda asele asetshenziselwa kakhulu ukucindezela okuphakathi nangaphezulu. Inani elincane kuphela lemikhumbi etholwa ngengcindezi esebenzisa amakhanda abunjwe ama-disc.

1. Indlela yokulungisa izitsha

(1) ukunyathela. Ukuzivumelanisa nokukhiqizwa kwesisindo, kucindezela amakhanda adongeni abiyelwe ngodonga futhi amancane adinga amasethi amaningi wokubumba amakhanda.

(2) Spin. Ilungele amakhanda aphezulu aphezulu futhi athambile. Ikakhulu embonini yamakhemikhali, ehilela kakhulu imisebenzi emikhulu kanye nevolumu ephansi, ilungele ikakhulukazi ukuphonswa. Amakhanda aval alungele ukuphotha, kanti amakhanda e-Dish awasetshenziswa kakhulu futhi amakhanda ayindilinga kunzima ukucindezela.

2

(1) Imishini yokushisa: Isitofu segesi. Ukushisa okufudumele kumakheni njengamanje kusetshenziselwa ukufudumeza, futhi uwoyela noma ukufudumeza kwegesi kusetshenziswa ngangokunokwenzeka. Ngoba ibonakala ngokuvutha okuhlanzekile, ukusebenza kahle okuphezulu, ukulawulwa kokushisa okulula, nobunzima ekubizeleni ngokweqile nasekubumbeni. Isithando somlilo kufanele sihlome ngedivayisi yokulinganisa lokushisa kanye nerekhoda yokushisa

.

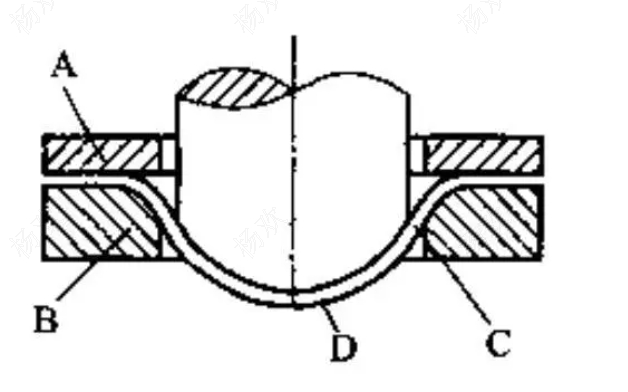

(2)Dish End Press. Kunezinhlobo ezimbili: isenzo esisodwa kanye nesenzo esiphindwe kabili.

Isenzo esisodwa sisho nje isilinda esinyantisayo futhi akukho silinda sabamba esingenalutho. Amafektri amancane amancane naphakathi nendawo ayisebenzisa. Amafektri amakhulu wonke asebenzisa isenzo esiphindwe kabili, okungukuthi, kukhona isilinda sabamba esingenalutho kanye nesilinda esinyantisayo.

Ukuhambisa okuphakathi kwemishini ye-hydraulic kumanzi. Kushibhile, kuhamba ngokushesha, akuzinzile, futhi akunazo izidingo eziphezulu njengemishini ye-hydraulic. Ukusebenza kahle kuphansi kunePress hydraulic, futhi izidingo zokuholwa azinamandla. Ukudluliselwa kwe-Hydraulic Press kuyazinza futhi kunezidingo eziphakeme zokubekwa uphawu nokuholwa.

(3) Sebenzisa amathuluzi, kufaka phakathi izinhlobo ezahlukahlukene zokubumba okuphezulu kwekhanda okuphezulu nokungaphansi, njll.

I-3. Izici ezithinta udonga oluwugqinsi lwekhanda

Izici eziningi zithinta ushintsho ebuqilini bekhanda, ezingafingqiswa ngokulandelayo:

(1) Izakhiwo ezibonakalayo. Isibonelo, inani elinciphayo lekhanda le-lead seal likhulu kakhulu kunalekhanda le-carbon seal.

(2) ukwakheka kwekhanda. Ikhanda elibunjwe nge-disc linenani elincane kakhulu lokuncipha, ikhanda le-spherical linenani elikhulu kakhulu lokuncipha, futhi ikhanda le-elliptical linemali ephakathi.

(3) Kukhudlwana irediyo ephansi ye-die fillet, incane inani elincanyana.

(4) Kukhudlwana igebe phakathi kokufa okuphezulu nangaphansi, okuncane inani elithambile.

(5) Isimo sokuthambisa sihle futhi inani lokuncipha lincane.

(6) Ukushisa okushisa okuphezulu, kulapho kukhulu inani lokuncipha.

4. Cindezela bese wenza thE DISH END

(1) Ngaphambi kokuba kucindezelwe ikhanda ngalinye, isikali se-oxide ekhanda esingenalutho kufanele sisuswe. Ukugcotshwa kufanele kusetshenziswe ku-isikhunta ngaphambi kokunyaza.

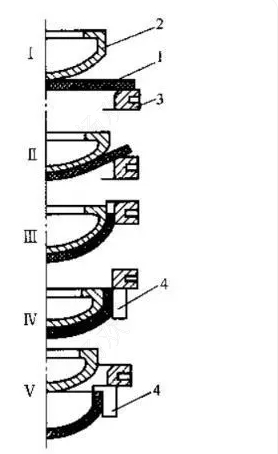

(2) Lapho ucindezela, ikhanda lingenalutho kufanele libekwe kakhulu ngesikhunta ngangokunokwenzeka. Ukuphambuka kwesikhungo phakathi kokungenalutho nokubumba okuphansi kufanele kube ngaphansi kwama-5mm. Lapho ucindezela ikhanda eligcwele, kufanele unakekele ukubeka ukuvulwa okuvela ku-elliptical on the angenalutho ngakunye njengezembazo ezinde nezifushane zesikhunta. Ngesikhathi sokucindezela, okokuqala, hlela umgodi punch ngesikhundla sokuvula esingenalutho bese ucindezela ukuphuma. Phitha kuze kufike endaweni ephakeme kancane kunendiza yesikhunta esingezansi (cishe i-20mm), bese ucindezela isikhunta esingenhla futhi. I-punch ye-hole nayo iwela ngasikhathi sinye ukucindezela ikhanda elisesimweni. Ngesikhathi sokucindezela, amandla okubhoboza adinga ukwenyuswa kancane kusuka kokuncane kuya kokukhulu futhi akufanele andiswe noma ancishiswe ngokuzumayo.

(3) Ikhanda elishisayo elishisayo lingadonswa kuphela ekubumbeni futhi liphakame lapho liphola ngaphansi kwama-600 ° C. Musa ukubeka endaweni. Musa ukubeka izingcezu ezingaphezu kwezimbili ngaphezulu komunye nomunye ngaphambi kokupholisa ekushiseni kwegumbi. Ngesikhathi sokunyathela okuqhubekayo, izinga lokushisa le-die likhuphuka lize lifinyelele ku-250 ° C futhi ukunyathela akufanele kuqhubeke. Umsebenzi ungaqhubeka kuphela ngemuva kokuthathwa kwezinyathelo zokupholisa ukunciphisa amazinga okushisa afe.

(4) Ikhanda eligcwele kufanele lenziwe ngesinyathelo esisodwa ngangokunokwenzeka. Lapho kungenzeki ukwakha ngasikhathi sinye ngenxa yezinkinga ezinemibandela, ukunakwa kufanele kukhokhwe ekhanda ngekhanda lapho kugxuma umgodi, futhi ukunakwa kufanele kukhokhwe ukuze kugcinwe ukushuba odongeni olufanayo e-flange yomgodi.

I-5. Hot Press Head forming hydraulic Press

Kuyashesha futhi kuvumelana nezimo ku-application application, kunokwethenjwa okuphezulu kokukhiqiza, futhi kungokomnotho futhi kuyasebenza.

■ Ilungele ikhanda le-Hot Press ekhanda.

■ Isakhiwo sabezindaba sisebenzisa isakhiwo sekholomu ezine.

■ Isilayidi sabamba sifakwe i-adaptha eshukumisayo eshukumisayo.

■ Ukushaywa yisilinda esinamafutha angenalutho kuyashintshwa.

■ I-Blank Holder Force kanye ne-Force Force ingashintshwa ngokuzenzakalelayo.

■ ungabona isenzo esisodwa kanye nezenzo eziphindwe kabili ngokulandelana.

I-6

■ Ilungele ukubuyiselwa emuva kwabezindaba kwabezindaba.

■ Isakhiwo sabezindaba sisebenzisa isakhiwo sekholomu ezine.

■ Umshini wesalula uhlome ngesikhunta esiphezulu, isikhunta esiphansi, ukuxhumana okubumbana, kanye nedivayisi yokushintsha okusheshayo.

■ I-Blank Holder Force kanye ne-Force Force ingashintshwa ngokuzenzakalelayo.

Isikhathi sePosi: Meyi-09-2024