1. Ukukhishwa kwamahhala

Ukuthethelela kwamahhala kubhekiswa endleleni yokusebenzisa ukusebenzisa amathuluzi alula ajwayelekile noma asebenzisa ngokuqondile amandla angaphandle angenalutho phakathi kwama-anvil angenhla angenawo izinsimbi ezingenalutho ukuze athole ukuthethelelwa kwe-geometric geometric nekhwalithi yangaphakathi.

Ukuthethelela kwamahhala kukhiqiza izinkomba ezimbizeni ezincane. Ebonisa imishini efana naleyo evuthelwa izando nemishini yokushicilela ye-hydraulic isetshenziselwa ukwakha izikhala ukuthola izikhala ukuthola izici ezifanele. Ukukhishwa kwamahhala kwamukela indlela eshisayo yokuvuselela.

Inqubo yamahhala yokwakha ifaka inqubo eyisisekelo, inqubo yokusiza, nenqubo yokuqeda.

Inqubo eyisisekelo yokumangalisa mahhala iyakhathaza, ukudweba, ukubhoboza, ukugoqa, ukusonteka, ukuguqula, ukuguqula, njll. Kepha izinqubo ezintathu ezisetshenziswa kakhulu ekukhiqizeni kwangempela zikhungathekisa, ukudweba, nokushaya.

Inqubo Yokusiza: Inqubo yangaphambi kokukhubazeka, njengokucindezela umhlathi, ucindezela onqenqemeni lwe-Ingot yensimbi, ukusika ihlombe, njll.

Inqubo Yokuqeda: Inqubo yokwehlisa izici zangaphandle zokukholelwa, njengokususa ukungalingani nokwakheka kwendawo evuthayo.

Inzuzo:

(1) Ukuguquguquka okuvuselayo kuhle, kungakhiqiza izingcezu ezincane ezingaphansi kwe-100kg. Futhi kungakhiqiza izingcezu ezisindayo kuze kufike ku-300t.

(2) Amathuluzi asetshenzisiwe amathuluzi alula ajwayelekile.

(3) Ukwakhiwa kokwakheka kufanele kudale kancane kancane kungenalutho ezifundeni ezihlukile. Ngakho-ke, i-tonnage yemishini edingayo ukuze kwakhiwe ukubhekelwa okufanayo kuncane kakhulu kunalokho okufa.

.

(5) Umjikelezo wokukhiqiza umfushane.

Okubi:

(1) Ukusebenza kahle kokukhiqizwa kuphansi kakhulu kunalokho okufa.

.

(3) Abasebenzi banokuqina okuphezulu kwabasebenzi futhi badinga amazinga aphezulu obuchwepheshe.

(4) Akulula ukufeza ukusebenza kanye ne-automation.

2. Ukufa kwakha

Ukufa Kwabakholelwa kubhekisele kwindlela yokwakha okutholwe kuyo ngokwakhela izikhala ngokufa ngokufa okukhethekile kokufa. Lokhu okukhiqizwa yile ndlela kuqondile ngosayizi, okuncane kwisibonelelo semisebenzi, kuyinkimbinkimbi ngesakhiwo, kanye nokuhola phezulu.

Kuhlukaniswe ngokwemishini esetshenzisiwe: Ukufa kwakha ngesando, kufa u-Crank Press, kufa umshini okhalwayo emshinini wokucindezela, njll.

Izinzuzo:

(1) Ukusebenza kahle kokukhiqizwa okuphezulu. Ngesikhathi sokufa kwazo, ukuguqulwa kwensimbi kwenziwa emgodini ofayo, ngakho-ke ukwakheka okufunayo kungatholwa ngokushesha.

(2) Lokhu kungakhiwa ngezinkwa eziyinkimbinkimbi.

(3) Kungenza ukusatshalaliswa kwensimbi ukusatshalaliswa kube nengqondo kakhulu futhi kuthuthukise impilo yenkonzo yezingxenye.

.

(5) Gcina izinto zensimbi futhi unciphise ukulayisha umthwalo.

(6) Ngaphansi kwesimo samabhethri anele, izindleko zezingxenye zingancishiswa.

Okubi:

(1) Isisindo sokwenziwa kokufa silinganiselwe umthamo wokufa okujwayelekile kokufa, ikakhulukazi ngaphansi kwama-7 kg.

(2) Umjikelezo wokukhiqiza wokufa okufile mude futhi izindleko ziphezulu.

.

3. Qingqa ukwakhiwa

Ukuqalisa ukubhekisa kwinqubo ekhokhwayo lapho kudliwa khona umbhoshongo ovundlile wokujikeleza fan okuvuthayo ukuze adale imali yokuthola imali oyikhokhayo ukuthola imali oyifunayo.

I-Roll Recuting Deformation ingukuguquguquka okuyinkimbinkimbi kwezintathu. Iningi lezinto ezidaliwe ligeleza eceleni kwendlela yobude ukwandisa ubude be-billet, futhi ingxenye encane yezinto ezibonakalayo igeleza kamuva ukwandisa ububanzi be-billet. Ngesikhathi senqubo yokwakhiwa kwe-roll, indawo ephambanisa nesigaba sempande ye-billet iyehla ngokuqhubekayo. Inqubo yokwakhiwa kwe-Roll Rectise isebenzisa umgomo wokuqalisa kabusha ukuze uguqule kancane kancane.

I-Roll Receting ilungele izinqubo ze-defformation ezinjenge-shaft ezinjenge-Shefting, ukugoqa ama-slabs, kanye nokusabalalisa izinto zokwenza okuqondile. Ukukhishwa kwe-Roll kungasetshenziselwa ukukhiqiza izinduku zokuxhuma, izingcezu zokudonsa ezisontekile, ama-wrenches, ama-spikes emigwaqo, ama-hoes, amakhethini kanye nama-turbine blade, njll.

Uma kuqhathaniswa nokufa okujwayelekile kwe-die, ukukhishwa kwe-roll kunesimo sesakhiwo esilula semishini, ukukhiqizwa okuzinzile, ukudlidliza okuphansi nomsindo, okuguquguqukayo okulula, kanye nokusebenza okungcono kakhulu.

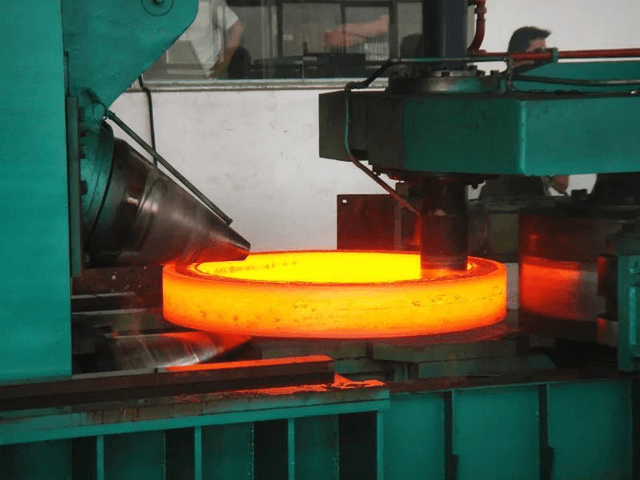

4. UTire uyafa

Ukufa kweTire kufa kuyindlela yokwakha esetshenziswa indlela yamahhala yokwakha ukuze wenze kube lula, bese uyikha esibayeni samathayi. Kuyindlela evumayo phakathi kokusolwa kwamahhala nokufa. Isetshenziswa kabanzi emabhizinisini amancane naphakathi nendawo anokufa okungatheni kwemishini yokufa futhi iningi lawo liyakha izando.

Kunezinhlobo eziningi zezikhunta zamathayi ezisetshenziswa ekubumbeni iTire, futhi ezivame ukusetshenziswa ekukhiqizweni zithambe, isikhunta se-buckle, isikhunta, isikhunta, isikhunta, njll.

Isilinda esivaliwe sifa kakhulu ukusetshenziselwa ukucelwa kokuthethelelwa kwe-rotary. Isibonelo, amagiya anabaphathi kuwo womabili amaphetho kwesinye isikhathi asetshenziselwa ukuzokhipha lokhu okuvukelayo. Ukufa kwesilinda okuvaliwe Ukufa Kwakha ukukhishwa okungenamkhawulo.

Ukuze uthole ubizo lwethayi elinobukhulu obuyinkimbinkimbi, kuyadingeka ukwengeza isikhunta ezimbili (okungukuthi, engeza indawo yokuhlukanisa) kusilinda isilinda ukwenza isikhunta esihlanganisiwe sokubumba. Futhi kungenalutho kwakhiwa emgodini owakhiwa isikhunta ezimbili.

Ifilimu eliyinhlanganisela livame ukwakhiwa izingxenye ezimbili, isikhunta esingenhla nesiphansi. Ukuze uhambisane nokufa phezulu nangaphansi futhi uvikele ukuthethelelwa kusuka ekushintsheni, ukuqondisa okuthunyelwe kanye nezikhonkwane zokuqondisa kuvame ukusetshenziselwa ukuma. Ukufakelwa kwe-clang kusetshenziselwa kakhulu ukukhiqiza izizathu ezingezona ezivukelayo ezinobunjwa obuyinkimbinkimbi, njengezinduku zokuxhuma, izinkomba, njll.

Uma kuqhathaniswa nokuthethelela kwamahhala, ukubulawa kweTire Ukufa kunezinzuzo ezilandelayo:

(1) Njengoba kungenalutho kwakhiwa emgodini we-die, usayizi wokuvuzayo uqondile futhi ingaphezulu bushelelezi.

(2) Ukusatshalaliswa kwezicubu ezihambisanayo kunengqondo, ngakho-ke ikhwalithi iphakeme.

. Njengoba ukwakheka kokubikwa kulawulwa yi-die cavity, kungenalutho kwakhiwa ngokushesha. Futhi ukukhiqiza kungu-1 kuye ku-5 amahlandla aphezulu kunalokho okumahhala.

(4) Kunamabhulokhi ambalwa asele, ngakho-ke isibonelelo semishini sincane. Lokhu akugcini nje ngokugcina impahla yensimbi kodwa futhi kunciphisa nemishini yama-manzi-amahora.

Okubi:

(1) Isando esababisayo esine-tonnage esikhudlwana siyadingeka;

(2) Ukukhishwa okuncane kuphela okungakhiqizwa;

(3) Impilo yenkonzo yesikhunta sethayi iphansi;

(4) Ngokuvamile kuyadingeka ukuncika kubantu abaningi ukuhambisa isikhunta samathayi ngesikhathi somsebenzi, ngakho-ke amandla abasebenzi aphezulu;

.

UZhengengxi uyaziwa kahleUkwenza umenzi womshini eChina, ukuhlinzeka ngezinhlobo ezahlukahlukene zokucindezela imishini, kufaka phakathi imishini yamahhala yokwakha, ukufela imishini,imishini eshisayo evuthayo, Imishini ebandayo yokukhomba, nemishini efudumele yokwakha, njll. Uma unezidingo, sicela uxhumane nathi.

Isikhathi sePosi: Jun-30-2023