Ngokuthuthuka okuqhubekayo kwezinto ezihlanganisiwe, ngaphezu kwamapulasitiki aqiniswe nge-fiber, amapulasitiki aqiniswe nge-carbon, amapulasitiki aqinisiwe, njll. Ama-Polymer Fiber aqinisiwe (CFRP) angasindi futhi izinto eziqinile ezisetshenziselwa ukwenza imikhiqizo eminingi esiyisebenzisa empilweni yethu yansuku zonke. Yigama elisetshenziselwa ukuchaza izinto ezihlanganisiwe ze-fiber-accosite ezisebenzisa imicu ye-carbon njengengxenye enkulu yesakhiwo.

Uhlu Lokuqukethwe:

1. I-carbon fiber eqinisiwe yesakhiwo se-polymer

2. Indlela yokubumba ye-carbon fiber eqinisiwe

I-3. Izakhiwo ze-polymer eqinisiwe yekhabhoni

4. Izinzuzo ze-CFRP

5. Okubi kwe-CFRP

I-6. I-Carbon fiber iqinisile ukusetshenziswa kwepulasitiki

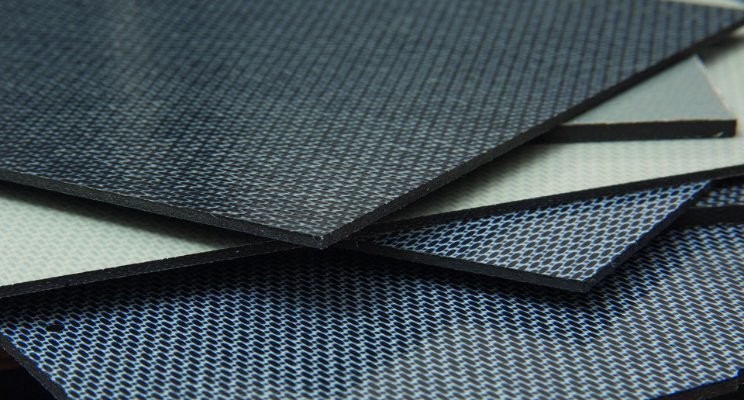

Isakhiwo se-polymer fiber aqinisiwe

I-Plastic ye-Carbon fiber eqinisiwe iyisitayela esakhiwe ngokuhlela izinto ze-carbon fiber endaweni ethile futhi zisebenzisa izinto ezinama-polymer. Ububanzi be-carbon fiber buncane kakhulu, cishe ama-microns ayi-7, kepha amandla alo aphezulu kakhulu.

Iyunithi eyisisekelo eyisisekelo ye-carbon fiber eqiniswe izinto ezihlanganisiwe yi-carbon fiber fillament. Izinto ezingavuthiwe eziyisisekelo ze-carbon filament zilandelana polymer polyacrylonitrile (Pan), Rayon, noma Petroleum Pitch. I-carbon ficaments bese yenziwa ibe izindwangu ze-carbon fiber ngezindlela zamakhemikhali nezemishini zezitho ze-carbon fiber.

I-polymer ebophayo imvamisa i-armosetting resin efana ne-epoxy. Amanye ama-thermosets noma ama-thermoplastic kwesinye isikhathi asetshenziswa, njenge-polyvinyl acetate noma i-nylon. Ngaphezu kwemicu yekhabhoni, ama-composites nawo angaqukatha ama-polyethylene we-aramid q, i-ultra-high high polyethylene, i-aluminium, noma imicu yengilazi. Izakhiwo zomkhiqizo wokugcina wekhabhoni fiber nazo zingathinteka ngohlobo lwezithasiselo ezingeniswe eMatrix eBonding.

Indlela yokubumba ye-carbon fiber eqinisiwe

Imikhiqizo ye-Carbon fiber ikakhulukazi yehlukile ngenxa yezinqubo ezahlukahlukene. Kunezindlela eziningi zokwakha izinto eziqinisiwe ze-polymer eziqinisiwe.

1. Indlela yokulala yesandla

Ihlukaniswe ngendlela eyomile (isitolo esilungiselelwe ngaphambili) nendlela emanzi (indwangu yefayibha kanye ne-resin glued ukuthi isetshenziswe). Ukulala kwezandla nakho kusetshenziselwa ukulungiselela ama-prePregs ukuze kusetshenziswe ezinqubweni zokubumba zesibili njengokubumba kokucindezela. Le ndlela yilapho amaSpredi ama-Carbon fiber wifu ahlanjululwe khona isikhunta ukwakha umkhiqizo wokugcina. Amandla kanye nokuqina kwezindawo zezinto ezivelayo zenziwa kahle ngokukhetha ukuqondanisa nokuluka kwendwangu yendwangu. Isikhunta sibe sesigcwaliswa nge-epoxy futhi selaphekile ngokushisa noma umoya. Le ndlela yokukhiqiza ivame ukusetshenziselwa izingxenye ezingacindezelwanga, njengezembozo zenjini.

2. I-Vacuum Yakha Indlela

Okwe-lamoted prepreg, kuyadingeka ukufaka ingcindezi ngenqubo ethile ukuyenza isondelene nokubumba nokuyelapha nokuyilolongela ngaphansi kokushisa okuthize kanye nengcindezi. Indlela ye-vacuum bag isebenzisa ipompo ye-vacuum yokukhipha ingaphakathi lesikhwama sakhe ukuze umfutho ongemuhle phakathi kwesikhwama futhi isikhunta sakha ingcindezi ukuze impahla eyinhlanganisela isondelene nokubumba.

Ngokwesisekelo sendlela ye-vacuum bag, indlela yokwenza i-vacuum bag-autoclave yasungulwa ngokuhamba kwesikhathi. Ama-autoclaves ahlinzeka ngokucindezela okuphezulu kanye nokwelapha ukushisa kwengxenye (esikhundleni sokulashwa kwemvelo) kunezindlela ze-vacuum bag-kuphela. Ingxenye enjalo inesakhiwo esihlangene ngokwengeziwe, ikhwalithi ephezulu yendawo, ingasusa ngempumelelo ama-bubble air (ama-bubble azothinta kakhulu amandla engxenye), futhi ikhwalithi ephelele iphakeme. Eqinisweni, inqubo yokubhalwa kwe-vacuum iyafana naleso yokunamathela kwefilimu kwefoni ephathekayo. Ukuqeda ama-bubble omoya kungumsebenzi omkhulu.

I-3. Indlela yokuhlanganisa yokuxhumanisa

Ukubumba kokucindezelakuyindlela yokubumba elungele ukukhiqizwa kwesisindo nokukhiqizwa kwesisindo. Izikhunta zivame ukwenziwa ngezingxenye eziphezulu nangaphansi, esizibiza ngokuthi isikhunta sabesilisa nesibungu sowesifazane. Inqubo yokubumba ukubeka i-mat eyenziwe nge-prepregs ibe yi-counter counter counter, futhi ngaphansi kwesenzo sokushisa okuthile kanye nengcindezi, bese kuvinjelwa i-capity, bese kugcwalisa i-caversing yokuthola imikhiqizo. Kodwa-ke, le ndlela inezindleko eziphakeme zokuqala kunalezo ezedlule, ngoba isikhunta sidinga kakhulu imishini ye-CNC enobungcweti.

4. Ukubumba okuvumayo

Ezingxenyeni ezinobukhulu obuyinkimbinkimbi noma ngesimo somzimba wenguquko, i-filament winder ingahle isetshenziselwe ukwenza ingxenye ngokufaka i-fillamel noma umnyombo. Ngemuva kokupholisa ukwelashwa okuphelele futhi ususe iMandrel. Isibonelo, izingalo ezihlangene ze-tubular ezisetshenziswe ezinhlelweni zokumiswa zingenziwa zisebenzisa le ndlela.

I-5. Resin Ukudlulisela Ukubumba

I-Resin Transfer Molding (RTM) iyindlela ethandwa kakhulu yokubumba. Izinyathelo zalo eziyisisekelo yilezi:

1. Beka indwangu elungiselelwe ye-carbon fiber elungiselelwe kusikhunta bese uvala isikhunta.

2. Kufakwa uketshezi oluwuketshezi i-thermosetting resin kulo, faka impahla eqinisayo, nokwelashwa.

Izakhiwo ze-polymer eqinisiwe yekhabhoni

(1) Amandla aphezulu nokuqina okuhle.

Amandla athile (okungukuthi, isilinganiso samandla ashukumisayo ekubuthakathaka) kwe-carbon fiber yizikhathi ezi-6 zensimbi kanye ne-17 amahlandla ayi-17 e-aluminium. I-modulus ethile (okungukuthi, isilinganiso se-modulus yoMoung to density, okuyisibonakaliso sokuqina kwento) ingaphezulu kwezikhathi ezi-3 zensimbi noma ze-aluminium.

Ngamandla aphezulu aphezulu, ungathwala umthwalo omkhulu wokusebenza. Ingcindezi yayo yokusebenza ephezulu ingafinyelela ama-350 kg / cm2. Ngaphezu kwalokho, kuncishelwa futhi kuyathandeka kunokuhlanzekile kwe-F-4 ne-braid yayo.

(2) Ukumelana nokukhathala okuhle nokugqoka.

Ukumelana kwayo ukukhathala kuphakeme kakhulu kunalokho kwe-epoxy resin kanye nokuphakeme kunalokho kwezinto zensimbi. I-Graphite Fibers iyazithathela futhi inenhlekelele encane yokuxabana. Inani lokugqokwa yizikhathi ezingama-5-10 zincane kunalezo zemikhiqizo ejwayelekile ye-asbestos noma ama-f-4 ama-braids.

(3) Ukuvuselelwa okuhle okushisayo nokumelana nokushisa.

Ipulasitiki eqinisiwe yekhabhoni eqinisiwe inokuphakelana okuhle okushisayo, futhi ukushisa okwenziwe ngengxabano kudilizwa kalula. Ingaphakathi akulula ukwedlula futhi ligcine ukushisa futhi lingasetshenziswa njengezinto ezinamandla zokubopha uphawu. Emoyeni, kungasebenza ngokuqine kuhla lokushisa lwe -120 ~ 350 ° C. Ngokwehliselwa kwe-alkali yensimbi yensimbi ku-carbon fiber, izinga lokushisa lensiza linganda futhi. Ku-inert gesi, izinga lokushisa layo eliguquguqukayo lingafinyelela cishe ngo-2000 ° C, futhi lingamelana nezinguquko ezibukhali ngokubanda nokushisa.

(4) Ukumelana okuhle okuhle.

Akulula ukuphinda usebenzise noma i-flutter, futhi futhi kungokwesisekelo esihle kakhulu sokunciphisa nokuncishiswa komsindo.

Izinzuzo ze-CFRP

1. Isisindo esikhanyayo

I-Plastics yendabuko yendabuko eqinisiwe isebenzisa imicu yengilazi eqhubekayo kanye ne-70% yengilazi Inhlanganisela ye-CFRP enesisindo esifanayo se-70% fiber ngokujwayelekile inobunzima bamaphawundi angama-0.055 nge-intshi ye-cubic inch ngayinye.

2. Amandla aphezulu

Yize ama-polymers aqiniswe yi-carbon angasindi, ama-composites e-CFRP anamandla aphezulu kanye nokuqina okuphezulu ngesisindo ngeyunithi ngayinye kunezinhlanganisela ze-fiber ze-Glass. Uma kuqhathaniswa nezinto zensimbi, le nzuzo isobala kakhulu.

Okubi kwe-CFRP

1. Izindleko eziphakeme

Izindleko zokukhiqiza ze-carbon fiber eziqinisiwe zepulasitiki azivunyelwe. Amanani entengo ye-carbon angahluka kakhulu ngokuya ngezimo zamakethe zamanje (ukuhlinzekwa kanye nokufunwa), uhlobo lwe-carbon fiber (i-aerospace vs. Kusisekelo se-pound-for-pound, i-vorgin carbon fiber ingaba izikhathi ezi-5 kuya kwezingama-25 kubiza kakhulu kune-fiber yengilazi. Lo mehluko mkhulu kakhulu lapho uqhathanisa insimbi ku-CFRP.

2. Ukuqhutshwa

Le yinzuzo nokungathandeki kwezinto zokwenziwa ze-carbon fiber composite. Kuya ngesicelo. I-Carbon Fibers iyimicu ye-Carbon ephathekayo futhi yengilazi iyafakelwa. Imikhiqizo eminingi isebenzisa i-fiberglass esikhundleni se-carbon fiber noma insimbi ngoba idinga ukufakwa okuqinile. Ekwenziweni kwezinsiza, imikhiqizo eminingi idinga ukusetshenziswa kwemicu yengilazi.

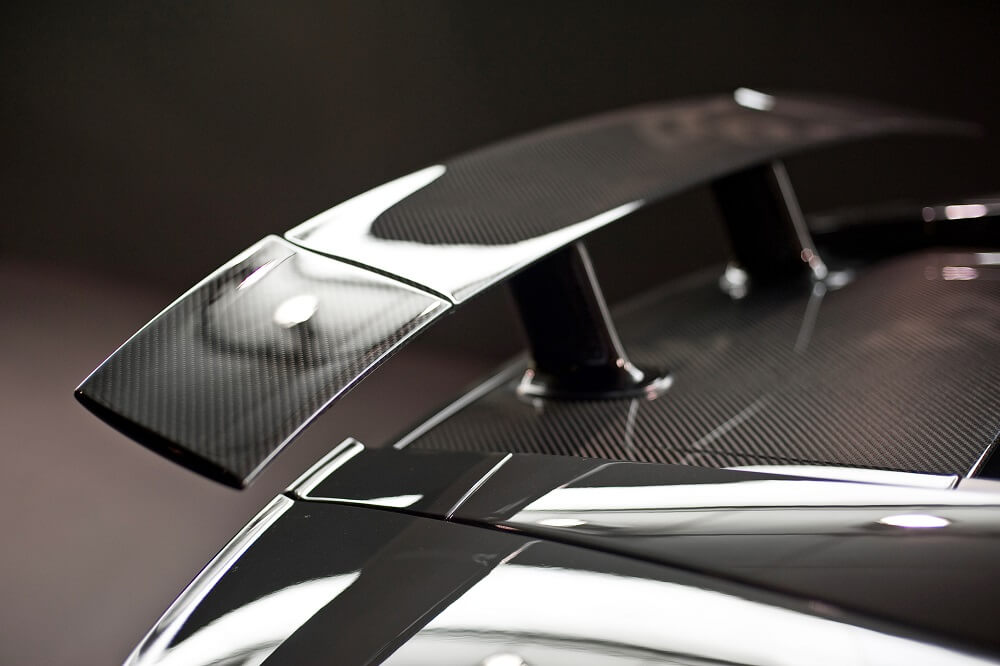

I-Carbon fiber iqinisiwe ukusetshenziswa kwepulasitiki

Ukusetshenziswa kwe-polymer eqinisiwe kwe-carbon

(1)njengokupakisha uphawu

Izindatshana ze-PTBE eziqinisiwe zingenziwa zaba izindandatho zokuvimbela ukuqina, ezivinjelwe, ezivinjelwe. Lapho isetshenziselwa ukubekwa uphawu kwe-static, impilo yensizakalo yinde, izikhathi ezingaphezu kuka-10 ubude kunaleyo epakisha ka-asbestos ejwayelekile. Kungagcina ukusebenza kokubekwa uphawu ngaphansi kwezinguquko zomthwalo kanye nokupholisa okusheshayo nokushisa okusheshayo. Futhi njengoba impahla ayinazo izinto ezilimazayo, akukho ukugqwala okukhohlisayo okuzokwenzeka ngensimbi.

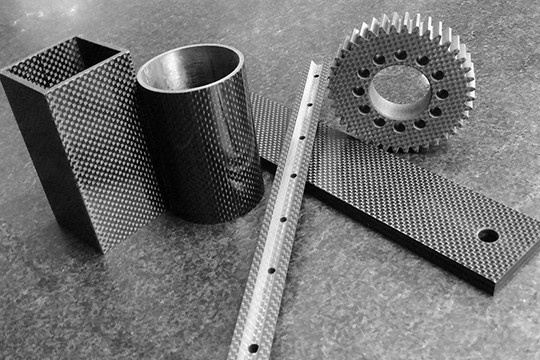

(2)njengezingxenye zokugaya

Isebenzisa izakhiwo zayo zokugcona, ingasetshenziswa njengoboshwe, amagiya kanye namasongo e-piston ngezinhloso ezikhethekile. Njengomthombo wamathuluzi wokugcoba wamafutha amathuluzi e-avias kanye nama-recoures we-tepi, amagiya athathwe kawoyela ama-Electris Trantion Diesel Locomotives (ukugwema izingozi ezibangelwa ama-compressors, njll. Ngaphezu kwalokho, kungasetshenziswa futhi njengezimboni zezemithi ngokusebenzisa izici zayo ezingezona ezinobuthi.

(3) Njengezinto zokwakha zesakhiwo ze-aerospace, izindiza, kanye nemicibisholo. Yayisetshenziswa okokuqala ekukhiqizeni izindiza ukunciphisa isisindo sendiza futhi ithuthukise ukusebenza kahle kwezindiza. Iphinde isetshenziswe kumakhemikhali, uphetrole, amandla kagesi, imishini, kanye neminye imboni njenge-rotary noma ukuguqula uphawu olunamandla noma izinto ezahlukahlukene ze-static seal.

UZhengengxi uchwephesheIfektri yabezindaba ye-Hydraulic eChina, ukuhlinzeka nge-Qualight-QuliatyComposite Hydraulic Pressngokwakha imikhiqizo ye-CFRP.

Isikhathi sePosi: Meyi-25-2023