Ukwakha igama elihlangene lokucekela phansi nokunyathela. Kuyindlela yokwakha esetshenziswayo esebenzisa isando, i-anvil, ne-punch yomshini ovuzayo noma isikhunta ukuze unikeze ingcindezi kokungabi nalutho ukudala izingxenye zesakhiwo nosayizi.

Yini ebizayo

Ngesikhathi senqubo yokwakha, konke kungenalutho kufinyelela epulasitiki ebalulekile kanye nenani elikhulu lokugeleza kwepulasitiki. Enqubweni yesitembu, okungenalutho kwakhiwa ikakhulukazi ngokushintsha isikhundla sendawo yendawo ngayinye, futhi akukho okugeleza ngopulasitiki ngaphezulu kwebanga elikhulu ngaphakathi kulo. Ukwenza ikakhulukazi kusetshenziselwa ukucubungula izingxenye zensimbi. Ingasetshenziswa futhi ukucubungula izinsimbi ezithile ezingezona izinsimbi, ezinjengeziplamisi zobunjiniyela, irabha, izikhala zobumba, izitini, kanye nokwakhiwa kwezinto ezihlanganisiwe.

Ukugoqa, ukudweba, njll. Ezandleni nasezimbonini zensimbi kugcwele wonke amapulasitiki noma ukucindezela. Kodwa-ke, ukuthi kusetshenziselwa ikakhulukazi ukukhiqiza izingxenye zensimbi, ngenkathi ukugingqa nokudweba kusetshenziselwa ikakhulukazi ukukhiqiza izinto zensimbi ezijwayelekile njengamapuleti, imichilo, amapayipi, amaphrofayli, kanye nezintambo.

Ukuhlukaniswa kokwakhiwa

Ukuqinisekiswa kuhlukaniswe ikakhulukazi ngokuya ngamazinga okushisa akwakheka kanye ne-deformation. Ngokwendlela yokwakha, ukuthethelela kungahlukaniswa izigaba ezimbili: Ukwakha nokunyathela. Ngokwezinga lokushisa le-defforational, ecela lingahlukaniswa ngokushisa okushisayo, okubandayo okubandayo, okufudumele, futhi kusolwa kabusha, njll.

1. Ukushisa okushisayo

Ukuvuselelwa okushisayo kuye kwakha okwenziwe ngenhla kokushisa kabusha kwensimbi. Ukwandisa izinga lokushisa kungathuthukisa ukuplaka kwensimbi, okuzuzisa ukuthuthukisa ikhwalithi ye-Workinsic ye-Working Amazinga okushisa aphezulu anganciphisa futhi ukumelana nokulimala kwensimbi futhi kunciphise ukuthambekela okudingekayoUkwakha imishini. Kodwa-ke, kunezinqubo eziningi zokuvuselela ezishisayo, ukunemba kwe-WorkPease kumpofu, futhi ingaphezulu alibushelelezi. Futhi ukuthethelelwa kuthambekele kwi-oxidation, ukuhumusha, kanye nomonakalo ovuthayo. Lapho umsebenzi we-workpiece mkhulu futhi ukhulu, okuqukethwe kunamandla aphezulu kanye neplastiki ephansi (njengokugoba ukugoba amapuleti angezekile, umdwebo wezinduku zensimbi ephakeme yekhabhoni, njll.), Futhi kusetshenziswe isikweletu.

Ngokuvamile amazinga okushisa ashisayo avuzayo yile: I-Carbon Steel 800 ~ 1250 ℃; Insimbi ye-Alloy Ehlelekile ngo-850 ~ 1150 ℃; I-Speed Speed High 900 ~ 1100 ℃; I-aluminium alloy evame ukusetshenziswa 380 ~ 500 ℃; alloy 850 ~ 1000 ℃; I-Brass 700 ~ 900 ℃.

2. Kubanda kubanda

Ukwakha amakhaza kuxoshwa okwenziwe ngaphansi kwamazinga okushisa okuvuselela kabusha kwensimbi. Ngokuvamile ukukhuluma, ukucekela ukubanda okubandayo kubhekisele ekufezeni izinga lokushisa lasekamelweni.

Ama-Wilshieches akhiwa amakhaza azakhela amazinga okushisa asekamelweni anokunemba okuphezulu nokunemba, izindawo ezibushelelezi, izinyathelo ezimbalwa zokucubungula, futhi zilungele ukukhiqizwa okuzenzakalelayo. Izingxenye eziningi ezakhiwe nezibanda ezibandayo nezibandayo zingasetshenziswa ngqo njengezingxenye noma imikhiqizo ngaphandle kwesidingo semishini. Kodwa-ke, ngesikhathi kubanda, ngenxa yeplastiki ephansi yensimbi, ukuqhekeka kulula ukwenzeka ngesikhathi sokukhubazeka kanye nokumelana nokukhubazeka kukhulu, kudinga imishini enkulu yokwakha.

3. Ukulimaza okufudumele

Ukwakha amazinga okushisa aphakeme kunokushisa okujwayelekile kepha kungangeqi ukushisa kabusha kabusha okubizwa ngokuthi ukubizwa ngemfudumalo. Insimbi isekashaywa kathulwa, futhi izinga lokushisa lokushisa liphansi kakhulu kunalokho okushisayo. Ukuqinisekiswa okufudumele kunokunemba okuphezulu, indawo ebushelelezi, kanye nokumelana okuphansi kwezenkolo.

4. I-ISORESTAL yakha

I-ISORTRAL EKUFANELE igcina izinga lokushisa elingenalutho njalo kuyo yonke inqubo yokwakha. I-ISORTRAL ECORTHERS ukwenza ukusetshenziswa okugcwele kweplastiki ephezulu yezinsimbi ezithile kumazinga okushisa afanayo noma ukuthola izakhiwo ezithile kanye nezakhiwo. I-ISORTRAL UCORTHER idinga ukugcina isikhunta nokuqukethwe okumbi emazingeni okushisa ahlala njalo, okudinga izindleko eziphezulu futhi kusetshenziselwa kuphela izinqubo ezikhethekile zokuvuselela, njengokuqanjwa kwe-superplastic.

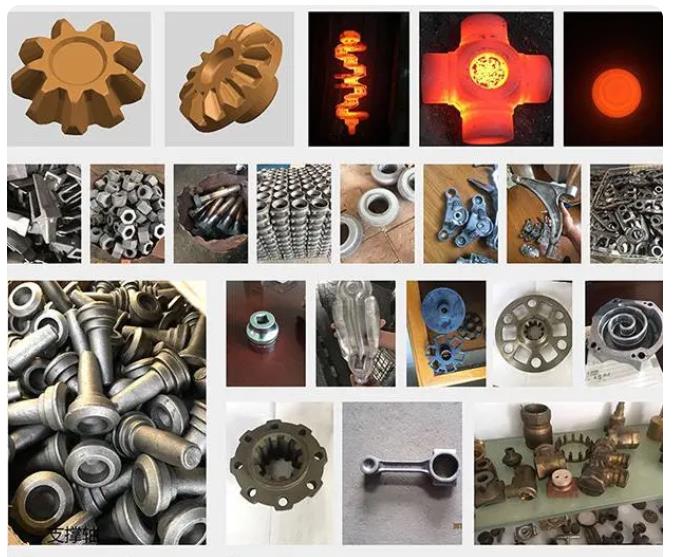

Izici zokwakha

Ukwenza kungashintsha ukwakheka kwensimbi futhi kuthuthukise izakhiwo zensimbi. Ngemuva kokuthi i-Ingot ishisa, ukulangazelela kokuqala, ama-pores, imifantu emincane, njll. Esikhathini esibikiwe Ama-dendrites asekuqaleni aphukile, enza okusanhlamvu kube mnandi. Ngasikhathi sinye, ukuhlukaniswa kwe-Carbide yasekuqaleni nokusatshalaliswa okungalingani kushintshiwe. Yenza umfaniswano wesakhiwo, ukuthola izikhombiso eziminyene, umfaniswano, ulungile, ube nokusebenza okuhle kakhulu, futhi athembekile ekusetshenzisweni. Ngemuva kokuthi ubiyelwe lukhubazekile ngokushisa okushisayo, insimbi inesakhiwo se-fibrous. Ngemuva kokukhuculwa okubandayo kwezoguquko, i-metal crystal iyahleleka.

Ukwenza ukwenza insimbi igeleze ngobuningi ukwakha i-workpiep yokwakheka okufunwayo. Ivolumu yensimbi ayiguquki ngemuva kokuthi ukuhamba kwepulasitiki kwenzeka ngenxa yamandla angaphandle, futhi insimbi ihlala igeleza iye engxenyeni yokumelana nencane. Ekukhiqizeni, ukwakheka kwesisebenzi somsebenzi kuvame ukulawulwa ngokuya ngale mithetho ukufeza izimo zezimbali njengokuqina, ukusunduza, ukunwetshwa, ukugoba, nomdwebo ojulile.

Usayizi womsebenzi owenziwe kahle unembile futhi uyafaneleka ukuhlela ukukhiqizwa kwesisindo. Ubukhulu bokubumba ukwakha izinhlelo zokusebenza ezinjengokuthiza, ukukhishwa, kanye nokuzinza izitembu zinembile futhi zizinzile. Ukusebenza kahle kwemishini esebenza kahle kanye nemigqa yokukhiqiza ezenzakalelayo yokukhiqiza ingasetshenziswa ukuhlela isisindo esikhethekile noma ukukhiqizwa kwesisindo.

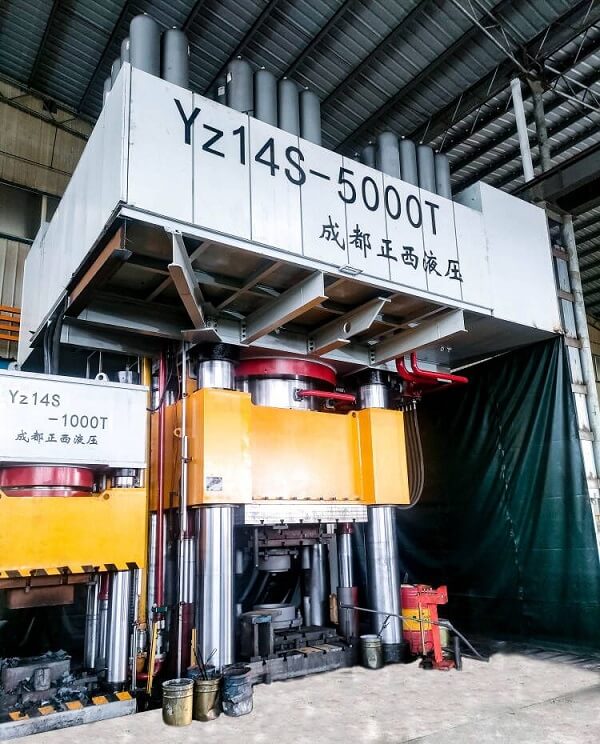

Imishini esetshenziswayo esetshenziswayo ifaka imishini ehlanganisa izando,Imishini ye-Hydraulic, nemishini yemishini. Isando esababizayo sinesivinini esikhulu somthelela, esizuzisa ukugeleza kwepulasitiki kwensimbi, kepha kuzoveza ukudlidliza. I-Hydraulic Press isebenzisa ukuklaba okungokomfanekiso, okuzuzisa ukufeza ngensimbi kanye nokwenza ngcono isakhiwo. Umsebenzi uqinile, kepha umkhiqizo uphansi. I-Mechanical Press inenhlamba ehleliwe futhi kulula ukuyisebenzisa ukwenza umsebenzi kanye ne-automation.

Umkhuba wokuthuthuka kokwakhiwa ubuchwepheshe

1) Ukuthuthukisa ikhwalithi ye-incrinsic yezingxenye ezakhiwe, ikakhulukazi ukuthuthukisa izakhiwo zabo zemishini (amandla, i-plastiki, ubunzima, amandla okukhathala) nokwethembeka.

Lokhu kudinga ukusetshenziswa okungcono komqondo wokuguqulwa kwepulasitiki kwezinsimbi. Faka izinto zekhwalithi engcono ngokwemvelo, njengensimbi ephethwe yi-vacuum kanye nensimbi ye-vacuum ebilisiwe. Yenza ukufudumeza kwangaphambi kokukhanyisa nokukhalela ukwelashwa okushisa kahle. Ukuhlolwa okuqinile okunamandla okuqinile kwezingxenye ezakhiwe.

2) Ngaphezu kwalokho bahlakulele ukunemba kwengqondo nokunemba kwezobuchwepheshe. Ukucutshungulwa okungapheliyo yisilinganiso esibaluleke kakhulu nesiqondisi soMkhakha wemishini ukuthuthukisa ukusetshenziswa kwezinto ezibonakalayo, ukuthuthukisa ukukhiqiza kwabasebenzi, futhi kunciphise ukusetshenziswa kwamandla. Ukuthuthukiswa kokufutheka okungekuhle kokufungiswa kwezikhala, kanye nobulukhuni obuphezulu, izinto ezivinjelwe ezivinjezelwe, izindlela zokwelashwa okudala kanye nezindlela zokwelashwa komhlaba, kuzobe kusiza ekusetshenzisweni okunwetshiwe kokunemba nokunemba kwesitembu sokunemba nokunemba.

3) athuthukise imishini evuthayo kanye nokwakha imigqa yokukhiqiza ngokukhiqiza okuphezulu kanye ne-automation. Ngaphansi kokukhiqizwa okukhethekile, ukukhiqiza kwabasebenzi kuthuthukiswa kakhulu futhi kwabe kuncishiswa izindleko ziyancishiswa.

4) Thuthukisa ama-Systems aguqukayo ekwakheni (ukusebenzisa ubuchwepheshe beqembu, ushintsho olusheshayo lokufa, njll.). Lokhu kunika amandla ukukhiqizwa okuhlukahlukene, ukukhiqizwa okuncane kwe-batch ukukhiqiza ukusebenza kahle kanye nemishini yokukhiqiza noma imigqa yokukhiqiza. Yenza umkhiqizo wayo nomnotho wasondela ezingeni lokukhiqizwa kwesisindo.

5) ukuthuthukisa izinto ezintsha, njengokubonisa izindlela zokucubungula zezinto ze-powder metallurgy (ikakhulukazi i-powder yensimbi enobumba (insimbi eluhlaza okwesikhashana, ipulasitiki eqinisiwe, nezinye izinto eziyinhlanganiso. Thuthukisa ubuchwepheshe obunjengokwakheka okukhulu, okwakha amandla aphezulu, kanye nokucindezela kwengcindezi ephezulu.

Isikhathi sePosi: Feb-04-2024