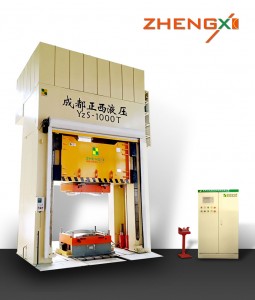

Umkhiqizo we-SMC wenza umshini we-hydraulic

I-Zhengengxi SMC BMC hydraulic Press nayo ibizwa ngokuthi yi-Hydraulic composites yokubumba cindezela, isetshenziswa ekubumbeni kokucindezela kwezinto ezihlanganisiwe ezifana ne-SMC, BMC, FRP, grp nokunye. Imishini yethu ye-SMC eyakha bese ucindezela ukunikela nge-Composete Industry Superiours Production Production, kanye nokulungisa nokuthuthukisa izinketho. Sihlinzeka ngemishini emisha ye-hydraulic yokubumba ye-hydraulic, futhi i-zhengxi aslo ihlinzeka ngohlu oluphelele lokulungisa nokuthuthukisa izinketho zokucindezela okukhona kokuxhuma kokuxhuma kwakho konke okwenziwe kanye namamodeli. Imishini yethu yokubumba ye-hydraulic isetshenziselwa ukukhiqiza izinhlobo ezahlukene zezimoto ezintsha, i-aerospace, izimboni njll.

Izici Zomshini

I-ItCit isetshenziselwa ikakhulukazi ukwakheka okubalulekile kwe-thermosetting (frp) plastics nemikhiqizo ye-thermoplastic. Ilungele ukwakhiwa kwe-SMC, BMC, DMC, i-GMT namanye amaningi namashidi.

Hhhydraulic uhlelo lufakiwe phezulu ngepulatifomu yesondlo, enobungane bemvelo, umsindo ophansi kanye nokulungiswa okulula.

I -MMult-Stage Speed tsress speed ehamba kancane, isikhathi esigcinwe ngokufanele.

thithi umsebenzi wokucindezela okuphezulu kwengcindezi ehamba kancane, efanelekile kwimikhiqizo ephezulu.

Qquick impendulo yohlelo, uhlelo lokulawula izinombolo.

Esithombeni sesayithi

Izinja

Lo mshini ulungele ikakhulukazi ukubumba okubonakalayo okuhlanganisiwe; Imishini inokuqina okuhle kohlelo nokunemba okuphezulu, impilo ephezulu kanye nokwethenjwa okuphezulu. Inqubo yokudla okushisayo ekwakheni ihlangabezana nokukhiqizwa kwe-shiffs / Day.

Izindinganiso Zokukhiqiza

| JB / T3818-99"Izimo Zobuchwepheshe zeHydraulic Press" |

| GB / T 3766-2001"Izidingo zobuchwepheshe ezijwayelekile ze-hydraulic systems" |

| GB5226.1-2002"Ukuphepha kwemishini-imishini kanye nemishini kagesi-ingxenye 1: Izidingo ezijwayelekile zobuchwepheshe" |

| GB17120-97"Cindezela Izidingo Zobuchwepheshe Bemishini" |

| JB9967-99"Umkhawulo womculo we-Hydraulic" |

| JB / T8609-97"Cindezela imishini ye-Welding technical izimo zobuchwepheshe" |

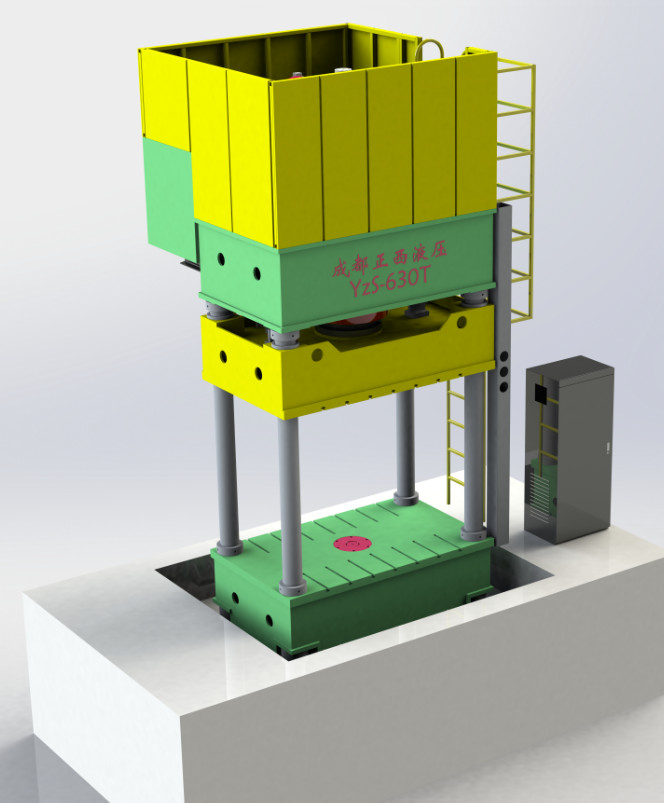

Umdwebo we-3D

H Uhlobo lwefreyimu

4 Uhlobo lwekholomu

Amapharamitha womshini

| Iisihloko | Umuvo | Yz71-4000t | Yz71-3000t | YZ71-2500T | YZ71-2000TT | Yz71-1500t | Yz71-1000t |

| Ukucindezela | kN | 40000 | I-30000 | I-25000 | I-20000 | I-15000 | I-10000 |

| UMax. Ingcindezi ewuketshezi | I-MPA | 25 | 25 | 25 | 25 | 25 | 25 |

| Ukukhanya kosuku | Mm | 3500 | 3200 | 3000 | I-2800 | I-2800 | I-2600 |

| Udwezwe | Mm | 3000 | I-2600 | 2400 | I-2200 | I-2200 | 2000 |

| Usayizi wethebula elisebenzayo | Mm | I-4000 × 3000 | I-3500 × 2800 | 3400 * 2800 | 3400 * 2600 | 3400 * 2600 | 3400 * 2600 |

| Ukuphakama ngaphezu komhlaba | Mm | I-12500 | I-11800 | I-11000 | 9000 | I-8000 | 7200 |

| Ukujula kwesisekelo | mm | I-2200 | 2000 | 1800 | I-1600 | I-1500 | 1400 |

| Ijubane eliphansi | Mm / s | 300 | 300 | 300 | 300 | 300 | 300 |

| Ijubane Lokusebenza | Mm / s | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

| Buyisela isivinini | Mm / s | I-150 | I-150 | I-150 | I-150 | I-150 | I-150 |

| Amandla aphelele | kW | 175 | 1350 | I-120 | 100 | 90 | 60 |

Umzimba oyinhloko

Umklamo womshini wonke wamukela design activikition complization futhi uhlaziya ngento esemncane. Amandla nokuqina kwemishini kulungile, futhi ukubukeka kukuhle. Zonke izingxenye zomshini zomshini womshini zifakwe yiplate yensimbi esezingeni eliphakeme yensimbi Q345B, efakwe nge-carbon dioxide ukuqinisekisa ikhwalithi ye-welding.

Isilinda

| Izingxenye | Fukwekwakha |

| Umphongolo wesilinda |

|

| I-Piston Rod |

|

| Izimpawu | Indandatho yekhwalithi yaseJapan Nok |

| Ipistoni | Iqondiswa yiplizwa yethusi, ukumelana okuhle, ukuqinisekisa ukusebenza kwesikhathi eside kwesilinda |

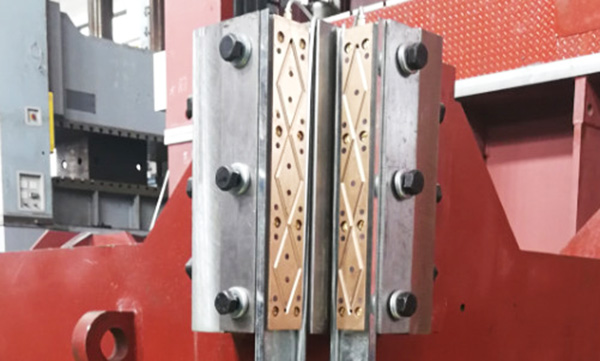

Insika

Izindlela zokuqondisa (izinsika) zizokwenziwaC45 insimbi evuthayofuthi ube nokuqina okunzima kwe-chrome 0.08mm. Futhi wenze lukhuni nokwelashwa okuvuthayo. Umhlahlandlela Umkhono wamukela umhlahlandlela we-Copper Guide, okugqokwa kakhulu futhi uthuthukisa ukuqina komshini

Uhlelo lwe-servo

I-1.Servo System Ukwakheka

Ukwakheka kohlelo lwe-2.Servo

| Ibizo | Mumenzi | Picebo | Aukunquma ngqo |

| I-HMI | Nokia |

| Impilo yenkinobho ihlolwe ngokuqinile, futhi ayilimali ngokucindezela izikhathi eziyi-1 million. Usizo lwe-Screen and Machine Fake, chaza imisebenzi yesikrini, chaza ama-alamu womshini, futhi usize abasebenzisi ngokushesha ukuba basebenzise ukusetshenziswa komshini

|

| Ibizo | Mumenzi | Picebo | Aukunquma ngqo |

| I-PLC | Nokia |

| Umugqa wokutholwa kwe-elekthronikhi uyacutshungulwa ngokuzimela, ngekhono elinamandla lokulwa nokuphazamisa Ukulawulwa kwedijithali kwe-servo drive kanye nokuhlanganiswa ne-drive |

| I-Servo Driver

| I-Yaskawa |

| I-capacitor yebhasi ephelele ithuthukiswa ngokuphelele, futhi i-capacitor enokuguquguquka kwezinga lokushisa okubanzi kanye nokuphila kwenkonzo ende kuyasetshenziswa, futhi impilo yethiyori inyuswa ngamahlandla ama-4;

Impendulo ku-50MPA yi-50ms, ingcindezi ngokweqile i-1.5kgf, isikhathi sokuthola ingcindezi singama-60ms, kanye nokuguquguquka kwengcindezi kungu-0.5kgf.

|

| Servo motor

| Isigaba Series |

| Idizayini ye-Simulation yenziwa yi-software ye-Ansoft, futhi ukusebenza kwe-electromagnetic kuphakeme; ukusebenzisa okuphezulu kwe-NDFEB ukuthokozela, ukulahleka kwensimbi kuncane, ukusebenza kahle kuphezulu, futhi ukushisa kuphakeme;

|

3.Advations of servo system

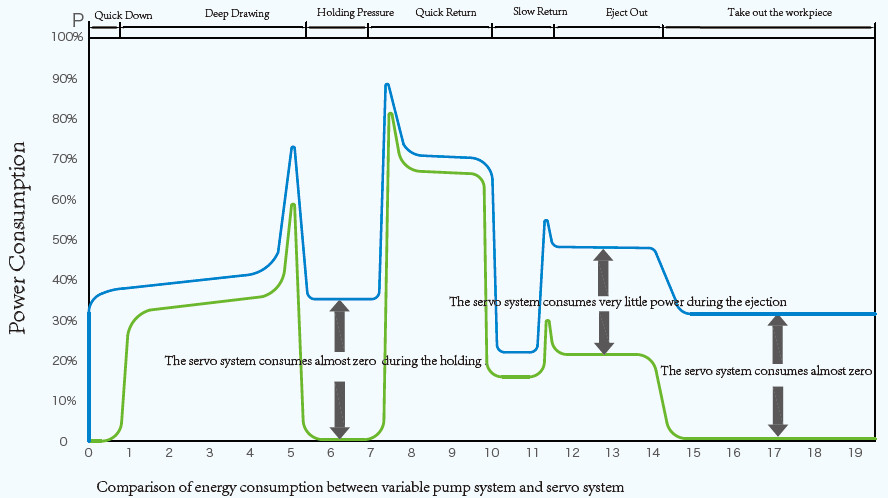

Ukonga amandla

Uma kuqhathaniswa nohlelo lwempompo yendabuko oluhlukile, uhlelo lwe-servo oil Pump luhlanganisa izici zomthetho wejubane olusheshayo lwemoto ye-servo motor kanye nezimpawu zokuzilawula zamafutha we-hydraulic, okuletha amandla amakhulu wokonga amandla, namandlaisilinganiso sokonga singafinyelela kuma-30% -80%.

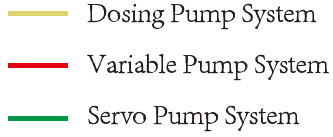

-Qeqesheka

Ijubane lokuphendula lishesha futhi isikhathi sokuphendula sifushane ngokuthi ama-20ms, athuthukisa ijubane lokuphendula lohlelo lwe-hydraulic.

Ukwenza kahle

Isivinini sokuphendula esisheshayo siqinisekisa ukunemba okuvulwa nokuvala, ukunemba kwesikhundla kungafinyelela ku-0.1mm, futhi ukunemba okukhethekile kokufika kwesikhundla kungafinyelela± 0.01mm.

Ukunemba okuphezulu, imoduli ye-PID algorithm ephezulu iqinisekisa ingcindezi yesistimu ezinzile nokuguquguquka kwengcindezi kokuncane± 0.5 Bar, Ukwenza ngcono umkhiqizo.

Ukuvikelwa Kwezemvelo

Umsindo: Umsindo ojwayelekile wohlelo lwe-hydraulic servo lungu-15-20 db oluphansi kunalokho kwephampu yoqobo eguquguqukayo.

Ukushisa: Ngemuva kohlelo lwe-servo lusetshenziswa, izinga lokushisa likawoyela le-hydraulic lincishisiwe liphelele, elithuthukisa impilo ye-hydraulic seal noma yehlise amandla okuphola.

Idivaysi yokuphepha

I-Photo-Electrical Safety Guard yangaphambili & emuva

Slide ukukhiya e-TDC

Ukuma kwesandla ezimbili

I-Hydraulic Support Insurance Insurance Insurance

Ukuvikelwa okugcwele ngokweqile: I-valve yezokuphepha

I-Liquid Level Alarm: Izinga lamafutha

Isexwayiso sokushisa samafutha

Ingxenye ngayinye kagesi inokuvikela ngokweqile

Amabhlokhi okuphepha

Ukukhiya amantongomane ahlinzekwa izingxenye ezinyakazayo

Zonke isenzo ze-PRESS zinomsebenzi wokuphepha kokuphepha, isib I-Slide ayikwazi ukucindezela lapho kusebenza ukusebenza kahle. Lapho ukusebenza kwezingxabano kwenzeka, i-alamu ikhombisa esikrinini sokuthinta bese ikhombisa ukuthi yini ingxabano.

Uhlelo lwe-hydraulic

Ithangi le-1.Ix setha uhlelo lokuhlunga olupholile oluphoqelelwe (idivaysi yezimboni yepuleti-hlobo lwamanzi, ukupholisa ngokujikeleza kwamanzi, lokushisa lamafutha ℃, qiniseka ukuthi umshini ucindezele ngokuqinile emahoreni angama-24.)

2.Uhlelo lwe-hydraulic amukele uhlelo lokuhlanganisa i-cartridge valve control system ngejubane lokuphendula okusheshayo nokusebenza kahle kokudluliswa okuphezulu.

3.Ithangi lamafutha lihlome ngesihlungi somoya ukuxhumana ngaphandle ukuze uqinisekise ukuthi amafutha e-hydraulic awangcolisiwe.

4.Ukuxhumana phakathi kwe-valve yokugcwalisa kanye nethangi likaphethiloli kusetshenziswa okuhlangene okuguquguqukayo ukuvikela ukudlidliza kusuka ekutholeni ithangi likaphethiloli futhi uxazulule ngokuphelele inkinga yokuvuza kawoyela.