Umshini wokuzivocavoca we-othomathikhi we-magnetic hydraulic Press

Izakhi zomshini: Cindezela (kufaka phakathi iphakethe le-wire wakggened), isiteshi sokuphawula se-hydraulic, iKhabhonethi Yokulawula Kagesi, umjovo kanye nohlelo lokuxubanisa, ithangi le-vacum; Ifreyimu yokubumba, umshini ozenzakalelayo ongena ngokuzenzakalelayo.

I-WhatsApp: +86 176 0282 8986

Ukucaciswa Okuyisisekelo Kwezobuchwepheshe

1) Uhlelo lwePump Pump Servo hydraulic lusetshenziselwa ukupholisa amafutha okucindezela ukuze uqinisekise ukucindezela, ukuqina kanye nokwethenjwa lapho umshini usetshenziswa ngokuqhubekayo isikhathi eside;

2) Ukusetshenziswa kwamandla okuphansi namandla okulondolozwa kwamandla. Ukusetshenziswa kwamandla komshini wonke kuyafana nalokho kwe-150-topress Press, kanti ukuphuma kwe-Shift kungu-53% ngaphezulu kwaleyo mishini yamathoni ayi-150;

3) Isizinda esibundayo esisezingeni eliphakeme senzelwe umgcini, futhi izingxenye ezibunjiweyo ezibunjiweyo zingahlukaniswa ngokushesha futhi zithathelwe indawo lapho isikhunta sithathelwa indawo, futhi isisekelo sokubumba sizimele;

4) Umzimba oyinhloko uyinsimbi ephelele yensimbi (noma i-Iron Iron), kanye nama-Wortables aphezulu nangaphansi, izisekelo zokubumba, izintambo ezibunjiweyo, izintambo zocingo ezisongelwe yinsimbi, zonke izingxenye zensimbi. Amandla aphezulu emishini, isakhiwo esihlangene, indawo yokufaka encane, elula ukuthatha okungekho emthethweni noma okuzenzakalelayo okungekho emthethweni;

I-5) Iyunithi eliphambili lesakhiwo samakholomu amane, esisebenzisa iphakethe le-wire-efakwe umoya eliphakeme.

6) yamukela isikrini sokuthinta nenzwa yokubona isikhombimsebenzisi somshini womuntu, ukulungisa iphutha kulula futhi kuyashesha;

7) Izingxenye ze-hydraulic zesiteshi samaphampu esiphakeme zisebenzisa ama-valves ase-Italy,

8) Yanelisa okuqukethwe kwamanzi okuphansi (okungu-34% kwamanzi okuqukethwe) umjovo ozenzakalelayo, ukuncela okuzinzile nokuthembekile

Icala Lenkampani

Amapharamitha womshini

| Ibizo | Umuvo | Thanda | |

| Isifanekiso | / | Yf-230t | |

| Amandla aphezulu esilinda | KN | I-2300 | |

| Ububanzi be-Cylinder | mm | I-360 | |

| Unhlangothi lwesilinda olungaphezulu | mm | 495 | |

| Force ophansi cylinder | KN | 1000 | |

| Ububanzi be-cylinder | mm | 25 | |

| Unhlangothi lwesilinda esiphansi | mm | 145 | |

| Isivinini se-RAM | Ukuvala | mm / s | >Umfana no-180 |

| Indlela ehamba kancane | mm / s | 2-10 | |

| Ukucindezela kancane kancane | mm / s | I-0.02-1.5 (Iyaguqulwa) | |

| Ukucindezela okusheshayo | mm / s | 0.1-2.5 (Kuhleliwe) | |

| Buyisela emuva | mm / s | >90 | |

| Ijubane le-Ejeva | Khipha | mm / s | 20 |

| Buyisela emuva | mm / s | 35 | |

| UMax. Isikhala samahhala se-Upper and Lower Stable | mm | I-1080 | |

| Usayizi ongasebenzi (Ubude be-X Ububanzi) | mm | I-1460 × 860 | |

| Iphakheji ye-Wire epholile ephezulu | / | I-COIL ye-AIR-PLEED KAKHULU | |

| UMax. Umjovo wevolumu yephampu yokujova | L | 4.1 | |

| UMax. Ukulayishwa kwe-mixer | L | Umfana no-180 | |

| Amandla aphelele omshini wonke | KW | 65 | |

| Isikhunta | / | Igebe le-550mm eliphakathi kwezisekelo zokubumba, ukuphakama 300mm | |

| Isikhathi sokujikeleza | S | <60 | |

Insika

Izindlela zokuqondisa (izinsika) zizokwenziwaC45 insimbi evuthayofuthi ube nokuqina okunzima kwe-chrome 0.08mm. Futhi wenze lukhuni nokwelashwa okuvuthayo.

Umzimba oyinhloko

Umklamo womshini wonke wamukela design activikition complization futhi uhlaziya ngento esemncane. Amandla nokuqina kwemishini kulungile, futhi ukubukeka kukuhle. Zonke izingxenye zomshini zomshini womshini zifakwe yiplate yensimbi esezingeni eliphakeme yensimbi Q345B, efakwe nge-carbon dioxide ukuqinisekisa ikhwalithi ye-welding.

Isilinda

| Izingxenye | Fukwekwakha |

| Umphongolo wesilinda |

|

| I-Piston Rod |

|

| Izimpawu | Indandatho yekhwalithi yaseJapan Nok |

| Ipistoni | Iqondiswa yiplizwa yethusi, ukumelana okuhle, ukuqinisekisa ukusebenza kwesikhathi eside kwesilinda |

Uhlelo lwe-servo

I-1.Servo System Ukwakheka

Isimiso sokulawulwa kwe-servo

I-Main Cylinder Upper Chamber efakwe inzwa yokucindezela, isilayidi esihlomele isilawuli sezinzwa. Ngokusho kwesiginali yengcindezelo yengcindezelo, isibonakaliso sempendulo yesikhundla, ukucindezela okunikezwa isiginali, isikhundla esinikezwe isibonakaliso sokubala isibonakaliso ukubala ijubane lokujikeleza lemoto ye-servo motor, ukulawula ukukhishwa kwempompo yengcindezi, isivinini kanye nokulawula isikhundla.

I-Admiss Adomets PID yokulungisa ingcindezi kanye nesikhundla, ngejubane le-servo motor ukulandelela ukulawulwa okuvaliwe. Ngokushintsha ijubane lemoto ye-servo, kungalawula ingcindezi, isivinini, isikhundla kanye namanye amapharamitha we-hydraulic Press, ngokuqeda i-valve yokulawula ye-hydraulic, i-flow control valve nezinye izingxenye ezisesifundeni sokulawulwa kwe-hydraulic nezinye izinto esisesifundeni se-hydraulic control ukuze kube lula.

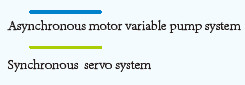

3.Advations of servo system

Ukonga amandla

Uma kuqhathaniswa nohlelo lwempompo yendabuko oluhlukile, uhlelo lwe-servo oil Pump luhlanganisa izici zomthetho wejubane olusheshayo lwemoto ye-servo motor kanye nezimpawu zokuzilawula zamafutha we-hydraulic, okuletha amandla amakhulu wokonga amandla, namandlaisilinganiso sokonga singafinyelela kuma-30% -80%.

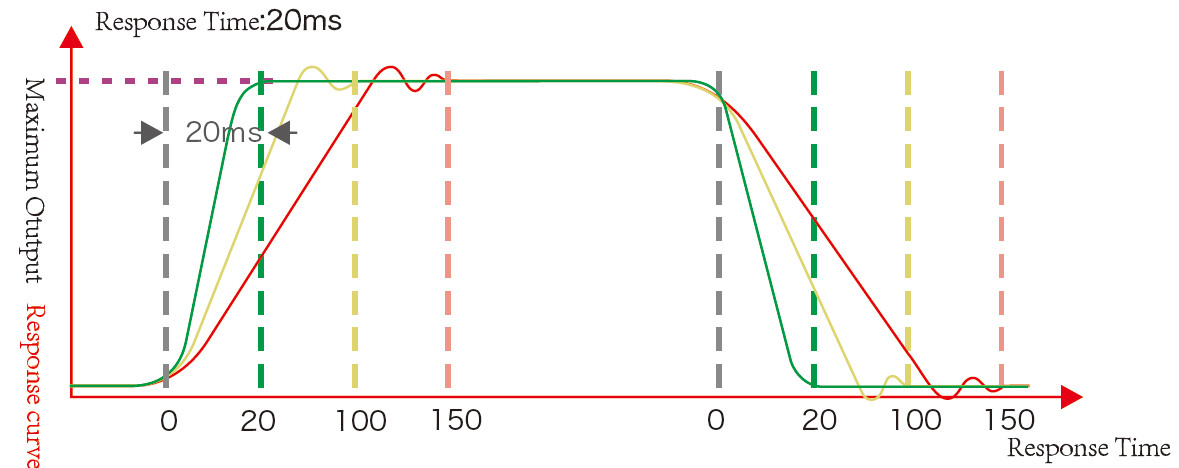

-Qeqesheka

Ijubane lokuphendula lishesha futhi isikhathi sokuphendula sifushane ngokuthi ama-20ms, athuthukisa ijubane lokuphendula lohlelo lwe-hydraulic.

Ukwenza kahle

Isivinini sokuphendula esisheshayo siqinisekisa ukunemba okuvulwa nokuvala, ukunemba kwesikhundla kungafinyelela ku-0.1mm, futhi ukunemba okukhethekile kokufika kwesikhundla kungafinyelela ± 0.01mm.

Ukunemba okuphezulu, imodule ye-PID algorithm ephezulu iqinisekisa ingcindezi yesistimu ezinzile nokushintshashintsha kwengcindezi kokungaphansi kwe-± 0.5 Bar, Ukwenza ngcono Umkhiqizo.

Ukuvikelwa Kwezemvelo

Umsindo: Umsindo ojwayelekile wohlelo lwe-hydraulic servo lungu-15-20 db oluphansi kunalokho kwephampu yoqobo eguquguqukayo.

Ukushisa: Ngemuva kohlelo lwe-servo lusetshenziswa, izinga lokushisa likawoyela le-hydraulic lincishisiwe liphelele, elithuthukisa impilo ye-hydraulic seal noma yehlise amandla okuphola.

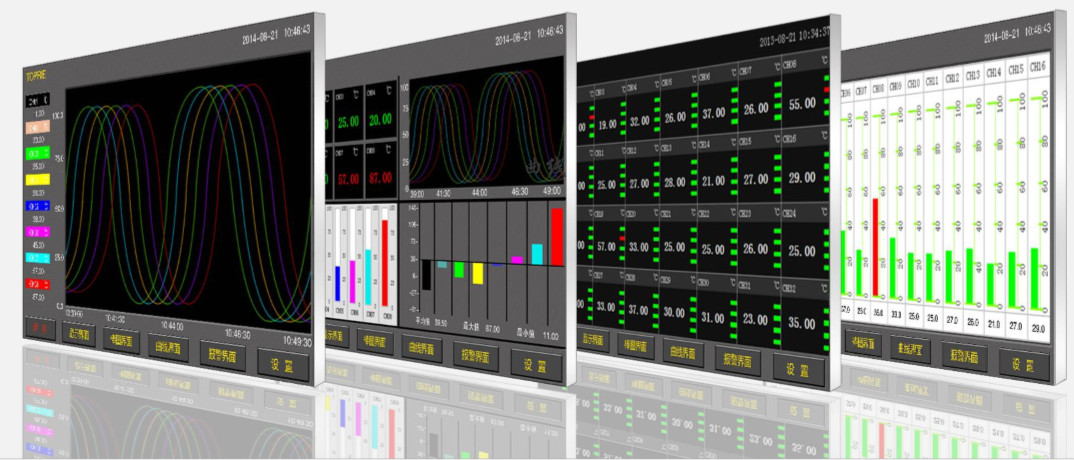

Okuzokwenzeka

I-Multi-Screen Industrial Host Computer ibona amapharamitha asemqoka kanye namaphutha wokuphakamisa ama-Press, ikakhulukazi kufaka imininingwane elandelayo eyisisekelo:

● ijika(I-MPA, ℃) ● Iphasiwedi ivikelwe ● Ukuboniswa kwedijithali ● Ukulandelelwa kwedatha

| Isikhundla sePlaten, 0 ku-Support Opencycle Timer Ukuqeda umoya | Ukuphapha umjikelezo, isigaba kuhlelo.Chofoza ingcindezi Isivinini

|

Idivaysi yokuphepha

I-Photo-Electrical Safety Guard yangaphambili & emuva

Slide ukukhiya e-TDC

Ukuma kwesandla ezimbili

I-Hydraulic Support Insurance Insurance Insurance

Ukuvikelwa okugcwele ngokweqile: I-valve yezokuphepha

I-Liquid Level Alarm: Izinga lamafutha

Isexwayiso sokushisa samafutha

Ingxenye ngayinye kagesi inokuvikela ngokweqile

Amabhlokhi okuphepha

Ukukhiya amantongomane ahlinzekwa izingxenye ezinyakazayo

Zonke isenzo ze-PRESS zinomsebenzi wokuphepha kokuphepha, isib I-Slide ayikwazi ukucindezela lapho kusebenza ukusebenza kahle. Lapho ukusebenza kwezingxabano kwenzeka, i-alamu ikhombisa esikrinini sokuthinta bese ikhombisa ukuthi yini ingxabano.

Uhlelo lwe-hydraulic

Ubuso

Ithangi le-1.Ix setha uhlelo lokuhlunga olupholile oluphoqelelwe (ukupholisa yi-oyili chiller, lokushisa lamafutha ℃, qiniseka ukuthi umshini uqiniseke ungacindezela ngokuqinile emahoreni angama-24.)

2.Uhlelo lwe-hydraulic amukele uhlelo lokuhlanganisa i-cartridge valve control system ngejubane lokuphendula okusheshayo nokusebenza kahle kokudluliswa okuphezulu.

3.Ithangi lamafutha lihlome ngesihlungi somoya ukuxhumana ngaphandle ukuze uqinisekise ukuthi amafutha e-hydraulic awangcolisiwe.

4.Ukuxhumana phakathi kwe-valve yokugcwalisa kanye nethangi likaphethiloli kusetshenziswa okuhlangene okuguquguqukayo ukuvikela ukudlidliza kusuka ekutholeni ithangi likaphethiloli futhi uxazulule ngokuphelele inkinga yokuvuza kawoyela.

5.I-hydraulic kawoyela ipayipi yenziwa ikakhulukazi ngepayipi lensimbi engenamthungo, futhi indlela enkulu kawoyela yobubanzi iyavuthwa. Ukuxhumeka kwamapayipi kuxhunyiwe yi-sae flange ngangokunokwenzeka. Uhlobo lwe-butt welding olunomphumela omuhle we-welding futhi ngempumelelo luxazulula inkinga yokuvuza kawoyela okubangelwa ukufudumala okubi.